I don’t know, but I’m about to find out.

I’ve managed to clear out the PTFE insulator pretty well. I pulled the entire heater out of the extruder, turned up the heat a little, held the barrel lightly in plyers, and unscrewed the PTFE without a problem, and then turned the heat off. I then used a precision flathead screwdriver to follow the threads, popping/chipping the plastic out as I followed I went. However, I don’t know to what extent the threads are still intact. Since the PLA oozed into the threads, I have to think they’re messed up to some extent.

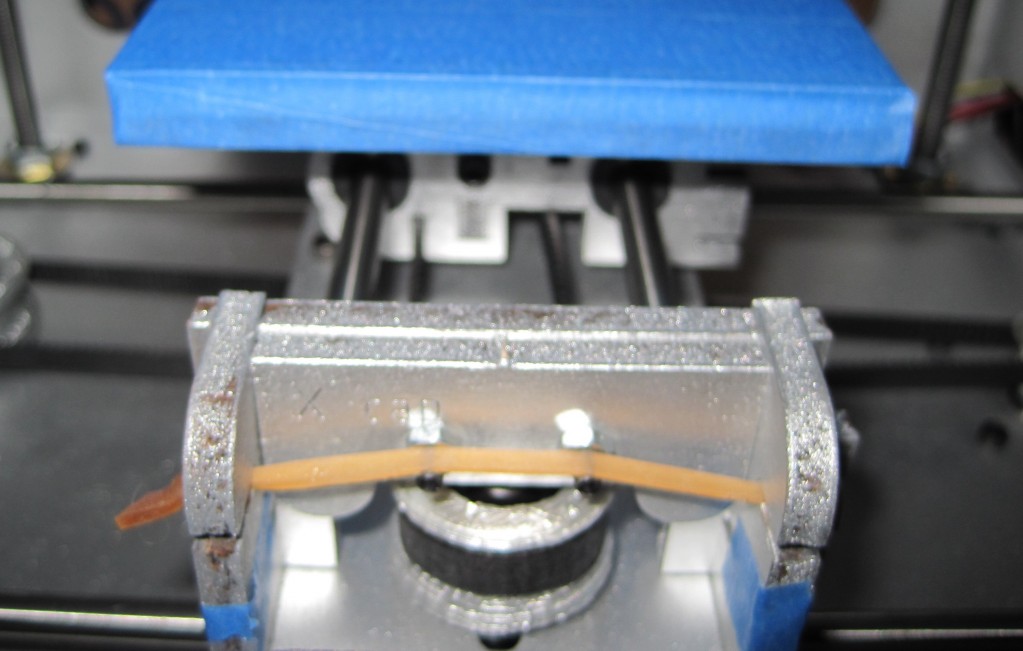

As for the barrel, I used a drill bit with the unsharp end wrapped in a rubber band. I rotated the bit using the rubber band as a grip to drill out the plastic. It actually worked really well for clearing out the barrel right to where I can see the barrel entering the nozzle. The inside is reasonably clean, but I still can’t put a filament into it freely.

I also had to take a precision screwdriver and follow along the threads on the barrel to chip out plastic. This went reasonably quickly. Once I was done the nut was able to screw on and off freely.

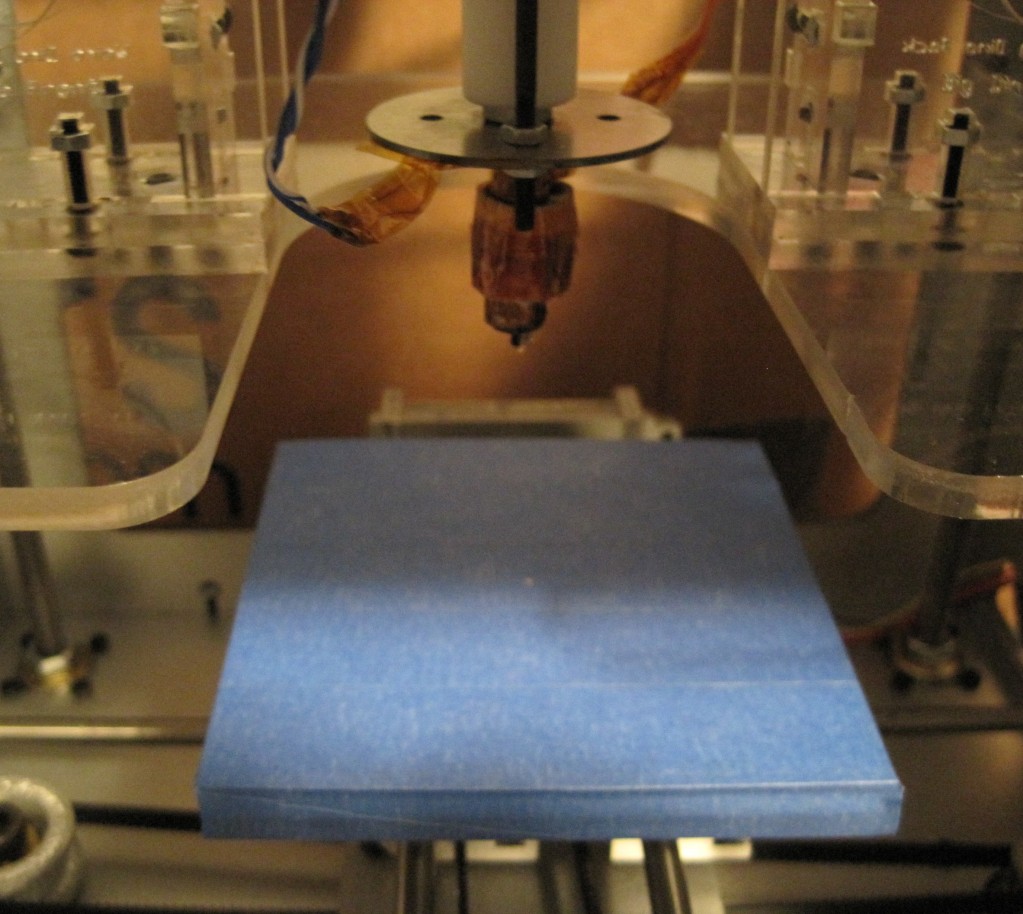

Now I’m left with a slightly discolored PTFE and a mostly clean barrel. I’ve got a spare PTFE insulator, but I’m hoping this one is salvageable. It still has threads and the barrel will screw in nicely.

Rick and Spacexula have suggested I use a torch to heat up the nozzle and let the plastic burn/fall out. But, this is a trick for another day with proper safety equipment.

Oh, and before I forget, Spacexula suggested keeping a ruined PTFE barrier to slice into insulating washers. I’m hoping I might be able to re-use the PTFE insulator, but this is certainly my backup plan.