My friend Spacexula just sent in this AWESOME suggestion on how to display 1000 origami cranes in a durable pleasing way.1 2 I’m going to give you a link to his website and blog, but before you click, know that the top post on his site today is very NSFW.3 Spacexula suggests:

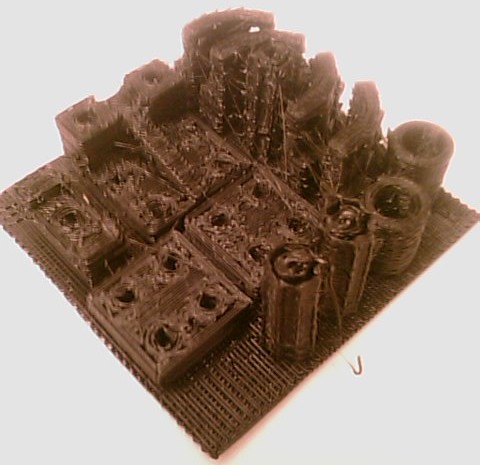

Cast all the cranes into a clear block of resin.

Can be picked up locally for around $20 a gallon.

If you suspend them all on fishing line stringers you could likely fit them all in a single concrete casting tube

http://www.homedepot.com/p/SAKRETE-8-in-x-48-in-Concrete-Form-Tube-65470075/100321209

I freaking LOVE this idea. The only thing I would need to test first is whether the resin would stick to the cardboard form creating a cloudy cardboard layer on the outside of the resin tower. That said, I love love love this idea and feel quite committed to it already.

Default Series Title- I should mention, this is not the first time I’ve blogged with the title, “Spacexula to the rescue!“ [↩]

- Photo courtesy of John Abella [↩]

- Okay, you asked for it… Don’t blame me. [↩]