…only in a way that is far less wordy and verbose than the manner in which I would typically attempt to describe the sorts of things I am thinking about.

“”The way you improve your iPad isn’t to figure out how it works and making it better. The way you improve the iPad is to buy iApps. Buying an iPad for your kids isn’t a means of jump-starting the realization that the world is yours to take apart and reassemble; it’s a way of telling your offspring that even changing the batteries is something you have to leave to the professionals.”

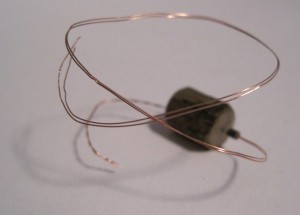

This is part of what is at the core of the Maker philosophy – empowering people to learn about the stuff of which civilizations are made, rather than being a plankton-like consumer/spectator. When something goes wrong, you don’t have to take it back to the store or call the (*shudder*) Geek Squad. 1

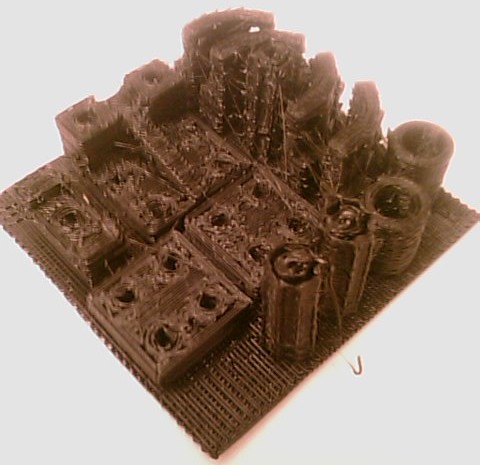

This is the heart of civilization, improving upon the work of prior generations. You have the luxury of being smarter than Einstein and wiser than Oppenheimer with 20-20 hindsight. You can know everything they know and improve upon it all. You can fix it yourself. 2 You have all of the tools you need right now, in your home right now. You can use the stuff you already have to build the tools you need to build absolutely anything within imagination.