Problem: Broken crayons, useless crayon bits, or crayon shavings. Crayola has their own crayon making system – a cross between an easy-bake-oven and little molds. However, I don’t think it is quite versatile enough. Plus, why pay $20 for what could be accomplished easily for $0.20 worth of plastic parts?

Solution: A printed crayon mold!

Description: Crayons melt at about 128 – 147 degrees Fahrenheit, or up to about 66 degrees Celsius. ABS won’t melt until around 88-125 degrees Celsius, so there’s a wide margin for melting the paraffin wax crayons without distorting the mold.1

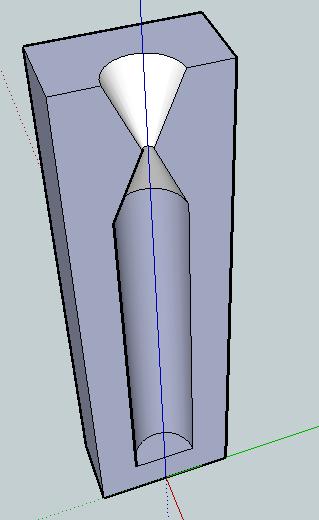

I would want at least three different molds – the normal crayon size, the fat crayon size, and then a triangular non-rolling crayon size. I’m picturing a two part mold for each, with the seam of the two parts running along the crayon lengthwise and a half funnel for pouring.

In addition to the half-mold, I’d also design a snug fitting square block for fitting the assembled mold into. That way you could stand it up and pour crayon wax into it.

Another potential use for this would be to place the pieces of crayon inside the mold, close it up, then heat. This would allow you to mend a broken crayon.

Usage: I can think of several different ways to use this mold. Frankly, I’m not sure which is easiest/most advisable/least advisable. There are easily several considerations:

- Assembly:

- The mold could be assembled with crayon inside to be melted and repaired.

- Crayon pieces could be melted and then poured into the assembled mold.

- Crayon pieces could be placed in the funnel at the top of the mold, the entire system heated and crayon allowed to melt down into the mold.

- Melting:

- Crayon could be melted in a test tube or similar container in the oven, microwave, hot water bath (such as on the stove) or perhaps even open flame and poured into the mold.

- Crayon could be melted while inside the mold by placing the mold in a heat source (oven, microwave, hot water bath).

- Crayon could be placed in the funnel and allowed to melt down into the mold with the application of a heat source (oven, microwave, hot water bath, open flame?, or sunlight plus magnifying lens!)

- Cooling:

- Allowing to naturally cool to ambient room temperature.

- Placing in fridge.

- Placing in freezer.

- Placing in cold water bath.

I’m not sure which method of heating and cooling are optimal. Though I’d suspect it is preferable to apply the least amount of heat over the shortest period possible.

Variations: It would be interesting to create these molds in different shapes besides cylinders. You could top each one with a geometric shape, the head (or tail!) of some kind of animal or character, or something else entirely. You could mold crayons into spheres, blocks, chips, or little figurines. While not particularly sturdy, you could even mold them into building blocks or components of some larger device. A clever person could use some left over nichrome wire to build a heated metallic funnel.

- That said, my extruder isn’t pumping out plastic until it hits 200 degrees Celsius at least. [↩]