I’ve been fiddling with settings on my MakerBot for the last week or so trying to improve print quality. Skeinforge setting this, Skeinforge setting that. Up, down, left, right, set it to pi, increase the print temperature, decrease the raft radius, adjust the feedrate speed. Unfortunately, all I managed to do was decrease print quality. Over the last two days I noticed the filament was coming out fairly slowly and today I noticed I kept stripping the filament.

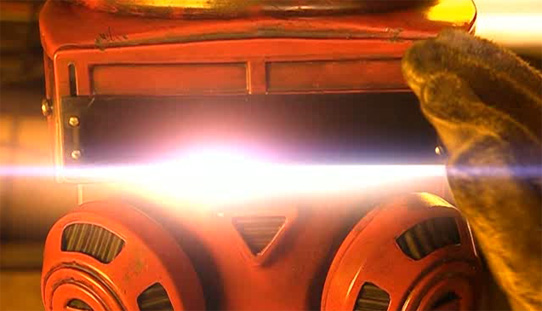

Well, it’s because ABS oozed down the barrel threads and around the nut. Yay. Time to break out the blow torch, eh?

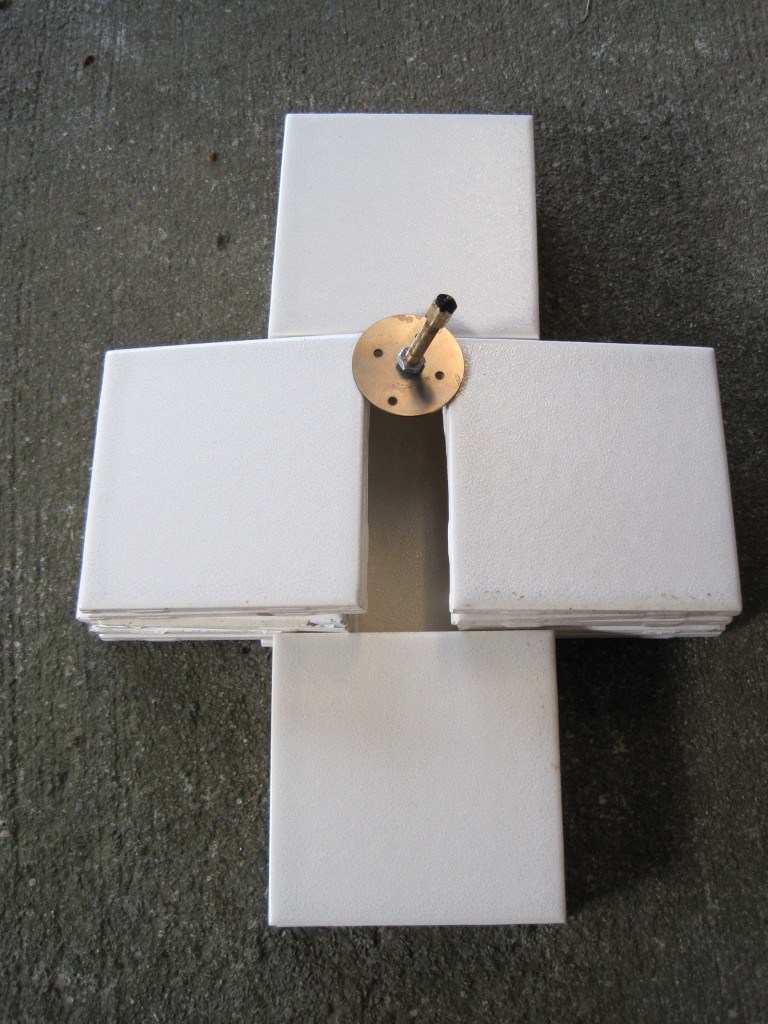

In disassembling (mostly) the extruder I found:

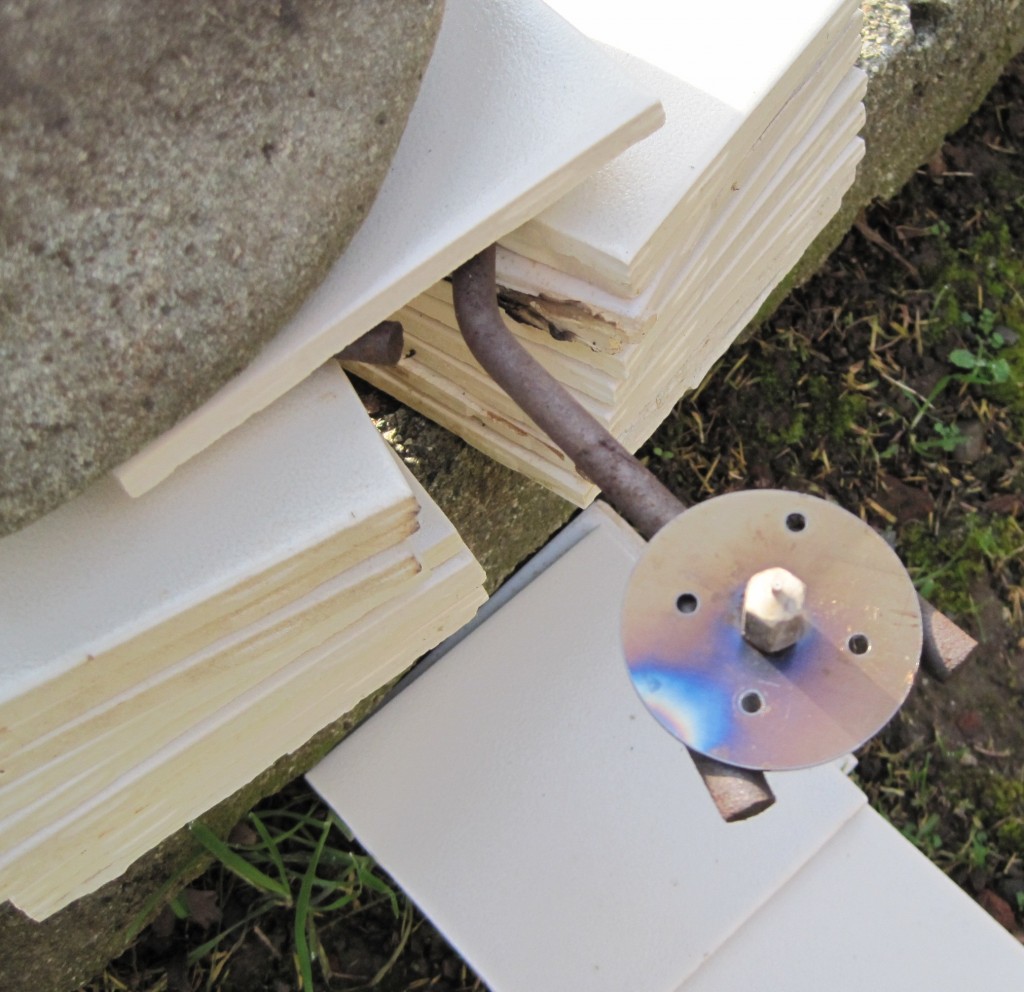

- Plastic down the threads of the barrel

- Plastic that had oozed onto the nut below the barrier

- Plastic still stuck inside the barrel itself

- A plastic plug inside the PTFE barrier and a slight bulge to the barrier

Plastic on the threads is not a huge deal, but not trial either – it mostly peeled off in spirals. Plastic on the nut is not a big deal – I pulled that off with some needle nose pliers. Plastic inside the barrel can be drilled out using my drill bit and rubber band trick.1

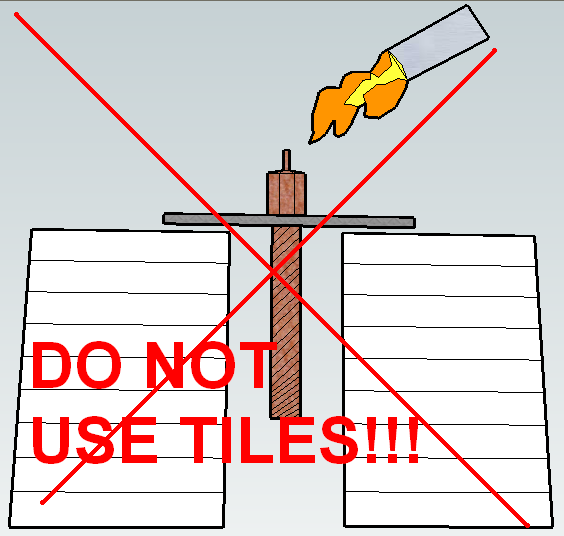

Plastic inside the PTFE barrier… well, now, that’s a different animal. I’ve succeeded once in rescuing my PTFE barrier from PLA oozing down the threads, but in that case there wasn’t a plastic plug inside the PTFE. The problem with a plastic plug inside the barrel is that I can’t really drill it out. If I try to drill it out from the top, I’ll probably still leave a bit of plastic where the barrier meets the barrel. If I try to drill from up from the bottom, I stand a good chance of ruining the part where the PTFE meets the barrel – creating a small gap where plastic can get stuck.

Thus, I think I will drill out the barrel and slap in a new PTFE barrier. Since I have this old (ruined?) one lying around, I have sliced off about a 2mm wafer to use as a washer on my next heater assembly. Using a small hacksaw blade did the trick – even if it left me with a relatively uneven slice.

While I’ve been putting off buying additional parts for my MakerBot, I think it’s time to invest in some new bits. I’m liking the MakerGear modular thermistor kit ($5), MakerGear modular heater core ($15), MakerBot heated build platform ($42), MakerBot SMT Soldering Toolkit ($50), and a hotplate.2