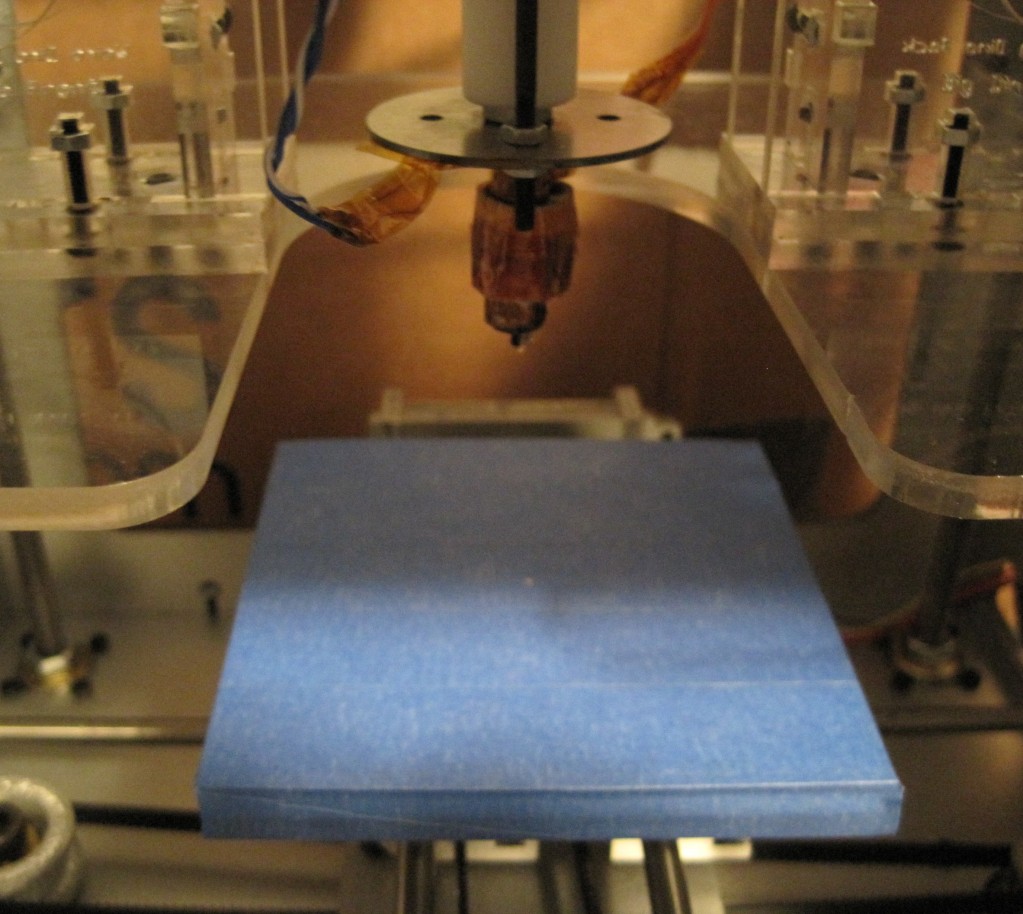

In order to step up production of my Beco Block collection (up to 30 pieces now) I ‘ve been using the Skeinforge multiply feature. Basically you feed it the number of columns and rows and it will make that many of your object in the final Gcode. For my own reference, and hopefully to help others, I’m putting down this little tidbit about Skeinforge’s multiply feature.

The “Multiply->Columns” feature creates additional sets of your object running from the front to the back of your build platform. So, if you have “Multiply->Columns” set to “3” and “Multiply->Rows” set to “1,” you will have three objects in a line running from the front of your Y platform to the back of your Y platform.

The “Multiply->Rows” feature predictably operates in a 90 degree rotation from the “Multiply->Columns” feature, with the additional parts running from side to side. So, if you have “Multiply->Rows” set to “3” and “Multiply->Colums” set to “1,” you will have three objects in a line running from the left to right of your Y platform.

This is a pretty handy feature for production. One caveat – more is not always better. In producing the Beco Block FF pieces I’ve discovered their combined warping is enough to ruin the entire print job (on my unheated build platform). I was printing 2 columns of 3 rows for 6 pieces at a shot. Unfortunately, with the additional warping I don’t have a single usable FF piece.