Earlier I had wondered about some of the challenges facing high resolution printing. Specifically, I had suggested that a lower resolution would be better for overhangs, speed, and (after the suggestion of Erik) interlayer adhesion.

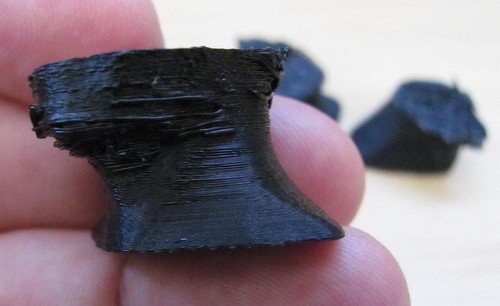

It looks like Dave Durant has a proof of concept with 1/4 of Disney’s head. 1 The layer height is unbelievably small – but as he points out:

Even smallish overhangs seem to be far harder to print at this layer height. I tried to print this one several times and it always went pear shaped as it got close to his chin, which is a pretty agressive overhang. Serious blobbage. :(

This certainly seems to demonstrate the flip side of my hypothesis – that thin layers are not good for printing overhangs. I’ve been printing with a layer height of about 0.33mm. This seems to give me enough resolution and overhang printability to make whatever I’ve needed so far. However, I think it also gives us a reason to have several different configurations for a MakerBot for each kind of plastic:

- Thin layer printing

- Good overhang printing

- High speed/thick layer printing

- Printing small holes?

What other kinds of profiles would you suggest?

- Dave – your Flickr account says all rights reserved. Obviously, I’m attributing this to you. If you would like me to remove the picture, I will do so. [↩]