Last night and tonight I have been tinkering with Flexo, my Thing-O-Matic, to install Jetty’s Sailfish firmware update. The setup text is very helpful, but not particularly optimized for a Thing-O-Matic with a MK6 extruder. I also found that I had to heavily modify the “start.gcode” and “end.gcode” to keep my bot from shaking itself to pieces. 1

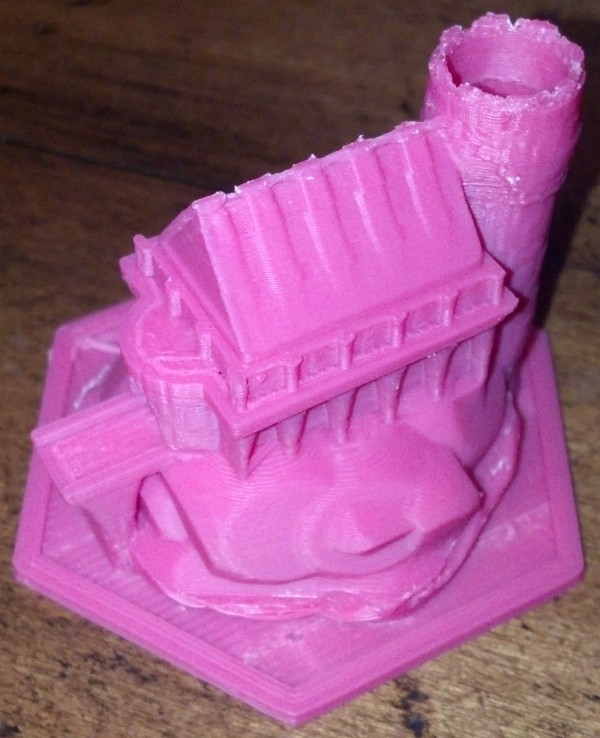

However, the results of combining Sailfish with ReplicatorG’s Print-O-Matic are impressive. Dutchmogul’s Keep, pictured above, was printed with a layer height of 0.15mm, 10% infill, all with a stock 0.5mm nozzle. That’s the very best resolution I’ve managed with my Thing-O-Matic, ever. At 0.15mm thick layers, I have a difficult time seeing the layers if the model is more than 6 inches from my face and the ridges on the vertical parts is difficult to discern with a fingertip.

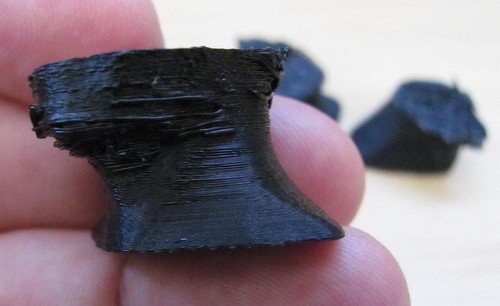

Now that I’ve finished that print I think I can push my ‘bot’s print resolution farther. I’m willing to bet I can print down to 0.10mm layer height if I re-applied the Kapton tape and did a better job of leveling the print bed. Also, one of the acknowledged challenges with 3mm filament based extruders is the pressure buildup that can lead to imprecise plastic deposits when dealing with non-contiguous parts. 2 Dialing in the Skeinforge “Retraction” or the Sailfish “Deprime” settings dialed in would really help with complex prints.

- The default “start.gcode” tried to home to the XY maximums and Z minimum – where there are no endstops. The default “end.gcode” did the same thing for some reason. I also had to modify the “start.gcode” so that the print head was better positioned for starting a print. [↩]

- By this, I mean that when you’re printing two or more features that are not connected, say for example a table that is legs-side-up, an extruder will naturally ooze a little bit of plastic as it travels between legs, leaving a thin spider web like strand. The “retraction” setting in Skeinforge is used to combat this, and does so fairly effectively in the case of a stepper based extruder. That setting reverses the extruder motor quickly just after the print head leaves a leg and then quickly moves extra fast forward as it gets to the next leg, which prevents the spider web effect. [↩]