At the beginning of the year I decided upon a few New Year’s Ambitions.1 I don’t like the idea of resolutions.2 Resolutions tend to be rule-driven. And, the problem with a rule-driven resolution is that once it’s broken, your whole plan is shot. An ambition, on the other hand, is a goal without a prescribed methodology for obtaining the goal.

Thus, New Year’s Ambitions. Here is my list of things that, if I were looking back upon all of 2013, I would like to see as a list of accomplishments.

- Lose weight and get more exercise

- Fold 1000 origami paper cranes

- Enter something in the California State Fair

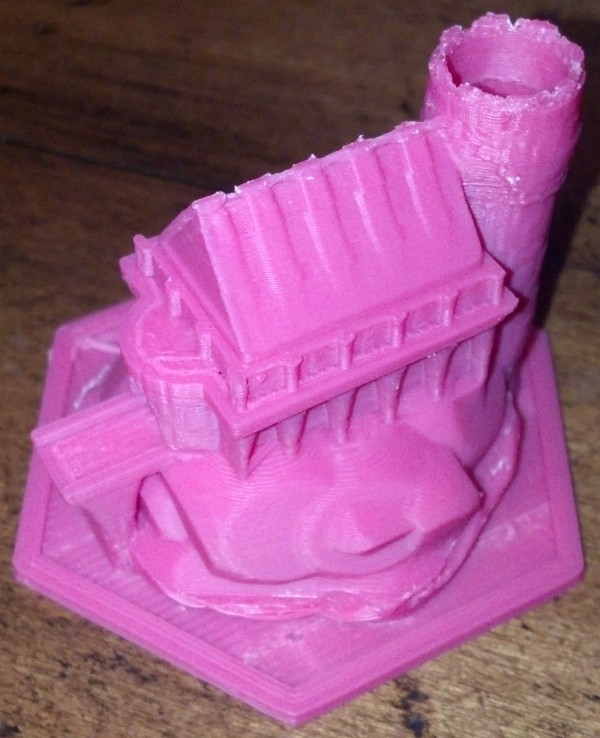

- Create and present something at Maker Faire 2013 Bay Area

- Blog more

- Write more WordPress plugins (’cause it’s fun!)

- Start another tiny fun business

More on these in a little bit…

Default Series Title