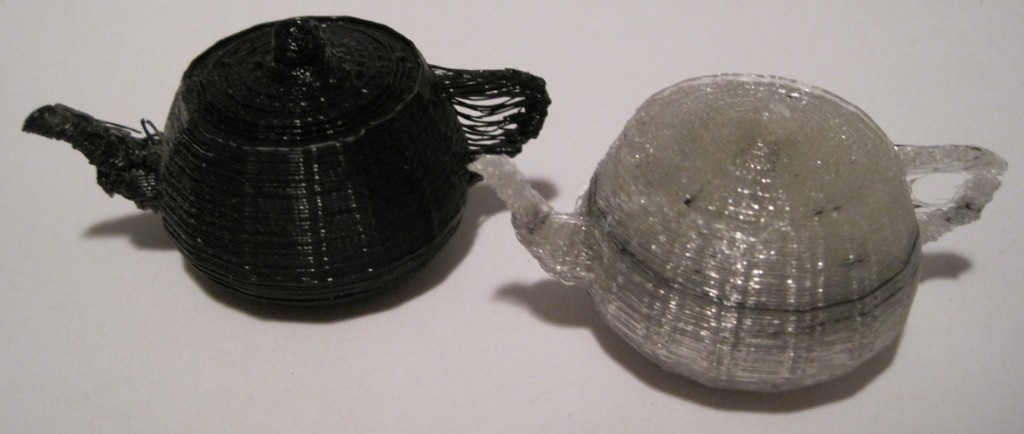

I’ve yet to print something big as I am still working out some of the black ABS specks from the extruder. Of the things I have printed so far, it looks like the PLA feels more brittle than the ABS. ABS will flex slightly when pressure is applied, whereas PLA seems to resist until it snaps. I like that I’m not wasting PLA by building rafts any more, now that the raft option is turned off in Skeinforge.

PLA takes a little longer to cool which has a few effects on a build. If the layer underneath is still molten and saggy, the layer on top will sag too. When an ABS part is done printing you’re basically ready to remove it. I find that a PLA object can still be a little soft for as much as 15-30 seconds after a build.

I’m loosing finer details on prints. I just reprinted the toy fire truck swivel. It turned out really nice except for the actual swivel part. Unlike the ABS model where the swivel snapped off immediately, the PLA model’s swivel was pretty solid (once it cooled and hardened). However, it came out too thin! As I watched it print, the PLA was so warm that it just stretched back during parts of the print – meaning the extruder nozzle made the full circuit, but the plastic stretched a little and pulled back closer to it’s last position. Uh, that may not sound like the clearest example.

Suffice it to say that small round details such as the swivel didn’t turn out very well. Which is pretty odd since similar small round detailed parts on the teapot did turn out well. I suppose part of the reason is the swivel was one small round part where the next hot layer was set down on the prior still hot layer, unlike on the teapot where the thin round spout would be drawn, then the body, then the thin round part for the handle and back over the body – so that by the time the next thin layer was set down the prior layer had cooled.