Unfortunately, Bender just stopped working. As I was keeping the nozzle warm while I was working on a new model, I looked up to see a flash of fire/spark shoot out from the nozzle area, ricochet off the build platform, and disappear. Looking at the RepG control panel I discovered that I wasn’t getting any readings from the thermistor. Not good.

The RepG control panel showed 0.0 as the temperature, so I shut the plastruder down, not wanting the heater to burn out of control. I restarted Bender and RepG – but I discovered that while I could control all three axes very slugishly, I could not move the extruder motor or detect temperature. I’m guess I couldn’t have increased the temperature either, but I didn’t want to try it since I couldn’t monitor the temperature. That about covers the symptoms.

In order to diagnose the problem I tried to isolate the various parts. I pulled all of the wires out of the extruder board. Then, while the wires were still out I tested the nichrome for resistance – still around 6ohms. Then I tested the thermistor – no connectivity. Again, not good. I tested the motor for continuity, and it was fine. Since the nichrome and motor seemed fine, that left the thermistor and extruder board. I popped a random resistor into the thermistor ports, but still couldn’t get a reading on it. Unfortunately, after several resets of the motherboard and extruder board, I still couldn’t get the motor to move or a reading from the thermistor. Also, I was getting an error message that the Payload was not big enough.

Rick Pollack of MakerGear suggested on the MakerBot Operators group that I reflash the extruder firmware. After several failed attempts, I finally figured out how to flash my extruder firmware from the Arduino environment by holding down the extruder reset button. This got rid of the payload error message as well as the avrdude errors and let me reflash the extruder.

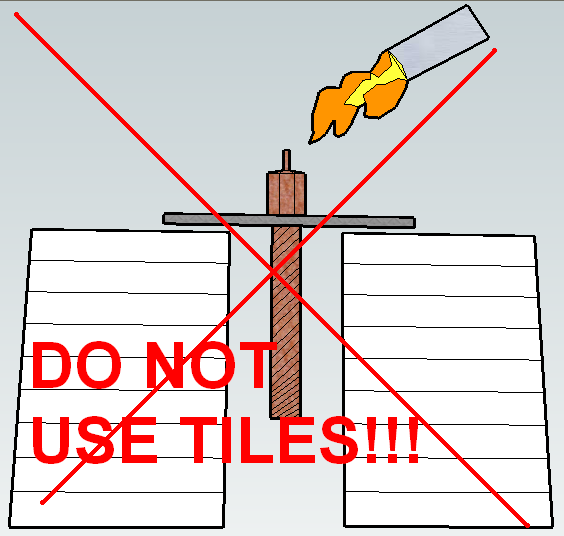

I pulled the entire extruder apart and did a little maintenance. I flossed the extruder pulley teeth, pulled all the stray bits of plastic out of the idler pulley wheel area, removed the old thermistor, unwrapped the nichrome (which was wound down and then doubled over itself as the original pictures in the wiki suggested) and rewrapped the nichrome (a single layer from the nozzle up the barrel following closely in the threads to make good contact everywhere) as suggested by several people in the MakerBot operators group. I then tested the nichrome again once it had been taped down for the proper resistance, check.

Once I pulled the thermistor out of the heater assembly, I tested the thermistor at its own leads, rather than at the wires soldered to it (in case the thermistor had come apart from the wires). Still nothing. I plugged a random resistor into the thermistor ports and was now able to get a reading off the extruder (as well as move the extruder motor). Concluding my problem was the thermistor, I forged ahead with a plan to replace it.

Luckily, I had placed an order for some PLA and nearly every single part needed for a secondary extruder (or what would be needed to fix a broken extruder) including a new thermistor. If you haven’t picked up backup parts, I highly recommend it.

I clipped the old thermistor off the wires, pulled out the new thermistor and taped it to a white piece of paper immediately, putting the tape across the leads just below the bead. I then bent the leads upwards, tinned them, soldered them to the wires, taped down the wires, pulled up the original piece of tape, and then sandwiched the thermistor in tape as per the instructions. I then plugged the heater, the motor, and the thermistor back into the extruder board – and was able to get a temperature reading, apply a little heat to the barrel, and move the extruder motor. I also noticed that this removed the sluggishness from the 3 axes stepper motors.

With the heater, motor, and thermistor working separately I put everything back together and reassembled the plastruder, plugged it back into the board and tested it again – readings, heat, and extruder motor working. I then popped it back into the dinos, did a test extrusion, and starting printing again.

“Rock on completely with some brand new components”