I’m so happy with the way this has turned out.

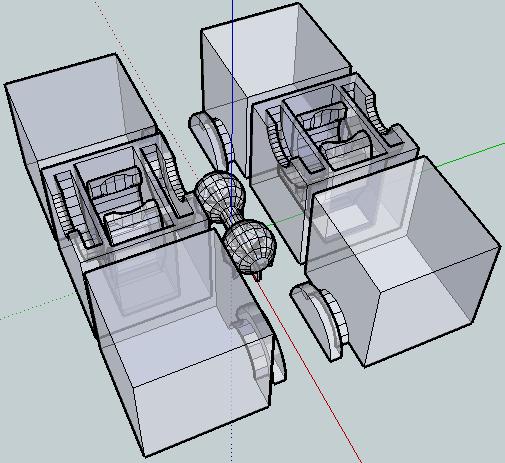

I’ve made a bunch of changes since the last revision of this printable 3x2x1 Rubik’s Cube puzzle:

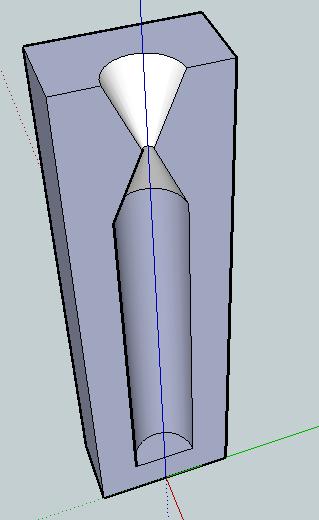

- I’ve totally redesigned the center barbell connector. I simplified the design, removed the five support struts for each end and replaced it with a single support strut and a flat hexagon in the center of the piece. The purpose of the hexagon is to give the barbell more contact area with the raft. One of the earlier drafts didn’t have as many supports or this flat hexagon, and it tore off the build platform partway through the build.

- I increased the diameter of the tube between the barbells. This enabled it to print easier, made it a little more sturdy, and decreased the wobbliness of the barbell when everything is assembled.

- I also shortened the entire barbell by 1mm, so that the entire puzzle is held together more closely.

- I made the flat semi-circular tabs slightly thinner so they rotate a little more freely.

- I significantly redesigned, thickened and simplified the two brackets that the barbell snaps into. It’s been able to easily withstand numerous couplings/decouplings as well as numerous rotations. With a few rotations, all parts now rotate easily.

- All of the parts fit together SO much better than my first draft held together with a nut and bolt.

- There is a slight bit of sideways flex that can occur with the use of the barbell. It is really minor and it actually seems to help the puzzle be more forgiving as you manipulate it. I see this more as a benefit than a design flaw.

The was one design choice on which I waffled. I considered making the center cubes non-identical, with one having half a barbell stick out and with the other having the internal connector you see now. This would have removed much of the sideways flex – since the barbell would be stationary. I did not go with this design choice because whether the puzzle used one barbell and two connectors or male/female center cubes, there would always be some flex caused by the use of a connector rather than a static pin. And, to be honest, I much preferred the symmetry of having everything assembled out of just three unique parts.

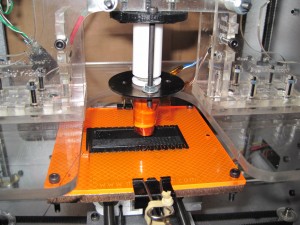

I know I’ve mentioned this before, but I really like the idea of a MakerBot printable toy that can be printed in one go and then assembled without tools or any additional hardware. I also think this would make a great MakerBot print demonstration.

I’ll post some pictures of the parts a little bit later.