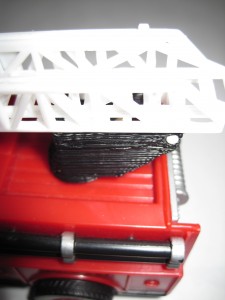

I was just floored by this recent post to the Make blog. This is the most amazing rubber band gun I’ve ever seen in my life. 1 It genuinely looks like a P90 from Stargate SG-1, including the way in which ammunition is loaded. 2 Even if weren’t for how realistic it looks, the mechanism is still fantastic. It apparently has a single shot/semi-automatic and fully automatic mode. Here’s what I can’t believe – that the creator of this magnificent toy thought it necessary to obscure their face in the video. I would be proud to call this my own.

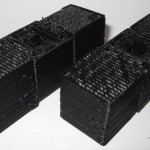

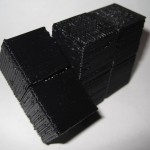

Since I’m on the topic, this next rubber band gun is also pretty cool.

The websites for the first gun is in Japanese, but the Google translation is pretty decent. The cut-away pictures show most of how the device works. Just as a head’s up, the way WordPress handles gallery photos puts all of these pictures into a single gallery even though I uploaded them at different times. The second gun appears to hold 8 shots and will “auto-return” the gun to its starting position. Although there are a few pictures of the piece from various angles, I don’t really understand how the auto-return mechanism works. If you’ve got an idea, I would appreciate your insight.

- Link to the video, if you’re tuning in via the RSS feed [↩]

- It holds 50 rubber bands! [↩]