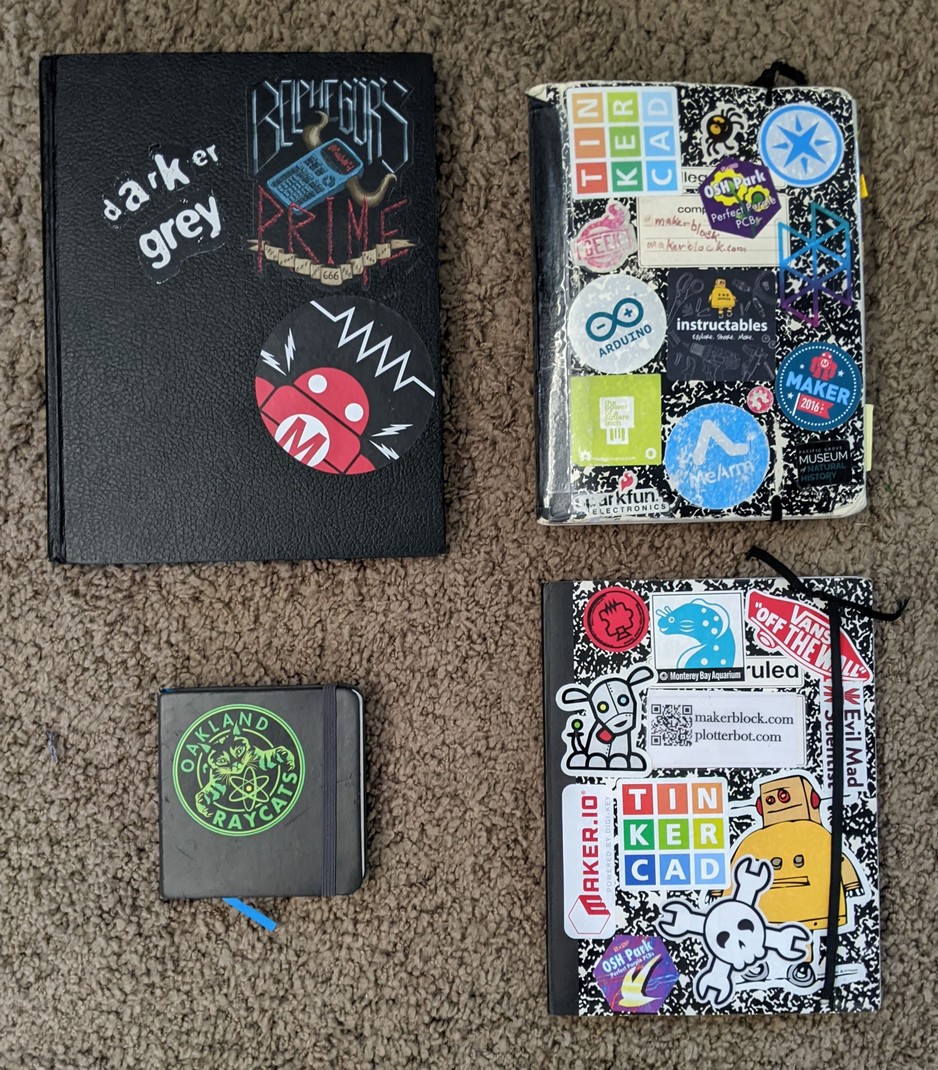

Over the last week I’d tried making a set of small rulers and straight edges I could keep in notebooks of various sizes. I’ve got a big heavy sketchbook, a thin college rule composition notebook with several DIY augments, and a very small sketchbook about 4″ square.

My idea was to make small credit card / ID card sized rulers, print them on paper, and then laminate them to keep in one or more notebooks. My first attempt a few days ago was serviceable1 – but lacking in aesthetics and functionality. (I’ll show some pictures below…)

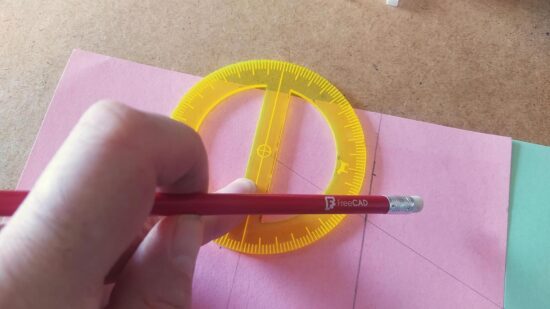

This morning I saw a Mastodon post by @concretedog234 demonstrating his use of a homebrew lasercut protractor.

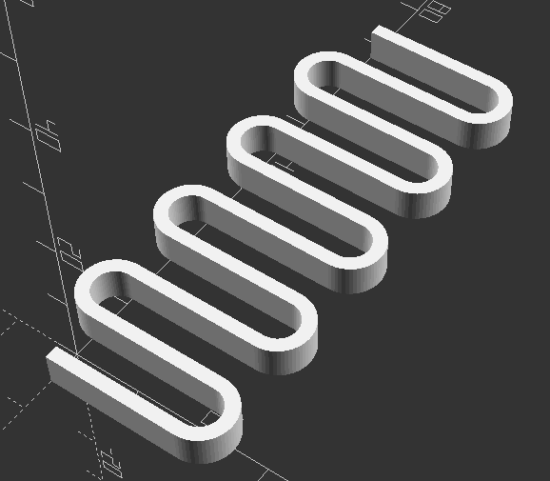

Inspired by @concretedog’s work, I embarked upon building my own in Inkscape, using some printable ruler I found online. A few design progress pics:

The basic process I used was:

- A few concentric circles for the overall protractor outline and semi-circle cutouts

- A longer 10 degree increment rotated 18 times (since it was a line at the top and bottom), a medium 5 degree increment rotated 36 times, and a short 1 degree increment rotated 180 times

- Edit -> Clone -> Create Tiled Clones

- Symmetry: P1: simple translation

- Shift: make sure the exponent is “0”

- Rotation:

- Angle row/column: 0, 5 degrees

- Rows/columns: 1 x 18

- Edit -> Clone -> Create Tiled Clones

- Then added the rulers minus the numbers (just looked cleaner)

- Three clones of the result, printed on paper, cut one out, cut out the semi-circle windows and center, laminated, then cut out the semi-circle windows and center again, ran it through the laminator for good luck

In an ideal world, I would also have created the ruler marks using @concretedog’s guide … I just hadn’t seen it until I got around to finishing this project. :)

Small Rulers and Protractors- built from PrintableRulers.net [↩]

- Someone I’ve been following for years and have come to think of as a parasocial friend [↩]

- Is following a fellow maker a parasocial relationship if you interact with them? [↩]

- Parasocial could be pre-friendship? [↩]