MakerBot Industries is giving away ten MakerBots to ten teachers at any educational level. Let’s just consider this my entry:

- Your name

- Uh. I’ll stick with “MakerBlock” for now.

- Your school’s name

- Sheesh. These are getting harder. Okay, how about “MakerBlock.com”? No? “MakerBlock U”?

- The address you’d like the MakerBot sent to if you are chosen

- Same place as my last order. ;)

- A paragraph describing how you would integrate the MakerBot into your curriculum. Include some description of the learning environment and what you teach

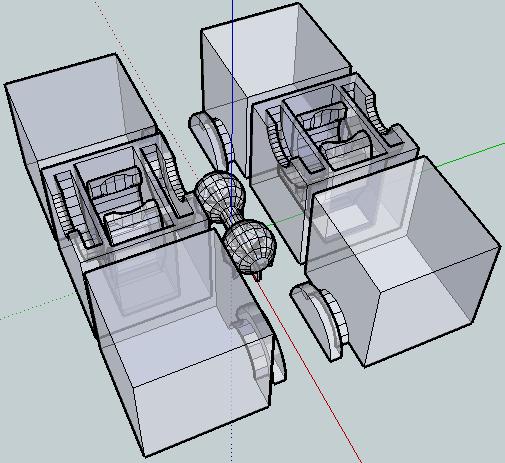

- I would integrate a MakerBot into my curriculum by using it as a demonstration of iterative design, digital fabrication, digital design, invention, and innovation. The learning environment is the whole freaking internet. 1 I teach digital plastic AWESOME.

- A lesson plan that you will implement if you get a MakerBot

- Pssh. Just one? I’ll give you THREE.

- You’ve got a MakerBot, a laptop, unlimited plastic and electricity. You are trapped in a mineshaft. How do you get out?

- You’ve got a MakerBot, a laptop, unlimited plastic and electricity. You are trapped in a mineshaft with a tiger. How do you get out?

- You’ve got a MakerBot, a laptop, unlimited plastic and electricity. You are trapped in a mineshaft with a tiger shark. How do you get out?

- Actually, according to Feedburner and Google Analytics, the number is just a few hundred people a day [↩]