I’m a big fan of Google Sketchup. I know it’s not open source, but damn it sure is easy to use. The other day I noticed this blog post about a new Sketchup STL Importer plugin. Earlier I had posted about other useful Sketchup plugins, and this one will probably make my list too. I’ve installed it, but not tried it out yet, so caveat emptor.

Month: April 2010

Two copies of Tetris and Achtung Baby

I just bought a Motorola Droid and was faced with a problem I always forget about when I get a new phone. If I want Tetris on the phone, I need to purchase it all over again. This makes me think back to the Actung Baby album by U2.

I’m fine with copyrights, even if the life span of copyrights has gotten ridiculous. However, it’s pretty ridiculous that I’ve actually shelled out for a copy of Actung Baby on cassette and again on CD. It’s the SAME music by the SAME band that I’ve ALREADY paid for. :/

How MakerBot Industries can help RepRap even more

Some people have suggested MakerBot is somehow stealing thunder from the RepRap project. 1 Here’s a super simple way every MakerBot sold could, in a very small way, help the RepRap project.

Why not put a copy of every Mendel part as an STL on the SD card that comes with the MakerBot? Actually, why not put Spacexula’s set of Mendel production STL’s?

This is a cheap and fast way to disseminate plans for RepRap files to people who are actually capable of making them.

- I totally disagree, but there you go. [↩]

Have we reached the bottom already?

Having reached the bottom of a market can actually be a very good thing. It means anyone who wants a set of RepRap parts can have them for as little as the market will bear. Right now there are lots of options for someone who wants to get involved in building a RepRap/RepStrap. You can get a MakerBot, RapMan, ShaperCube, Profound Devices, Isaac Mendel, or pick up a large selection of parts on eBay.

As an owner of a MakerBot, I’m far more likely to want to print up my own RepRap parts than buy them. However, each of Spacexula‘s Mendel print sets would probably take me 2-3 hours of print time plus about 15 minutes of human intervention/monitoring.1 I would of course also print up parts for any friends/family who wanted parts. 2 I’d be willing to do this to create my own Mendel, but the idea of spending three weeks3 , say $30 in plastic4 , and about six broken up over that three weeks fiddling with stuff5 makes me wonder if there’s a better way to make $300.00.

Setting that aside, I wonder where the bottom of the RepRap parts market is heading? Spacexula has suggested around $250 or so based upon the price for lasercut parts. I suspect the price of printed parts will always be higher than the price for lasercut or molded parts – because of the time involved. Lasercut parts can be cranked out as quickly as a lasercan cut. 6 Molded parts can be churned out as quickly as the poured material can be dried. Plus, no matter how nice lasercut/molded parts are – you still have a RepStrap, not a true RepRap. Assuming identical quality, I’m probably always going to be more interested in printed parts over alternatives.

- Such as setting up, warming up, untangling plastic, checking, peeling off, etc. [↩]

- At this point, this is purely theoretical/hypothetical since none of my family/friends are interested in their own RepRap. Hmm… Maybe I should talk about RepRap MORE??? [↩]

- A little over one sheet a day [↩]

- I haven’t weighed a sheet of Mendel parts, so this is pure conjecture. [↩]

- Assuming no extruder clogs, blocks, PTFE bulging, oozing down the threads, and problem free printing… [↩]

- How many phasers could a laser slice if a laser could slice phasers? [↩]

How to Raise Your MakerBot from the Dead

… or Happy Zombie Day!

My extruder is back online! Huzzah! Since I had it disassembled I made a few minor modifications.

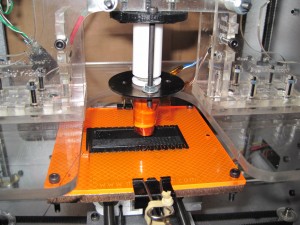

- I’ve added binder clips to the front and back edges of the build platform. I found that my acrylic build base is slightly deformed and probably getting more so with each build. This is a temporary fix while I get around to picking up a new build base.

- You’ll notice I’ve also added pieces of rubber band. I cut a long rubber band into two pieces about an inch long, tied them off to make small loops, and put them around the handles to the binder clips. I don’t want to take the handles out of the binder clips because then they’ll be difficult to move/remove/replace. But, as I printed they tended to vibrate creating unnecessary noise.

- When ABS oozed down my PTFE threads and around the barrel, I sliced off about 1mm to use as a washer between the nut and large washer. The reason I’ve heard suggested for the PTFE washer is that it keeps the large metal washer from acting as a heat sink. The nut is right on the barrel and is able to heat right up along with the rest of the barrel. When the large washer is pressed on the nut (as it is supposed to) it is able to absorb heat through the nut as well as it’s contacts to the barrel. The thin surface area contact between interior hole in the large washer and the barrel probably doesn’t allow for much heat to be transferred to the large washer.

- I’ve read it mentioned that wrapping an extruder with nichrome is a two person or three handed job. I’ve found it to be fairly easy with just my two hands.

- I use a small piece of kapton to tape the nichrome to the extruder head/nozzle oriented so that it is lined up parallel to the barrel. 1

- From the point where I can see the nozzle touch the barrel I leave about 2-3cm of nichrome hanging off the edge, with the rest of the nichrome pointed up towards the barrel.

- Then I wrap the nichrome up the barrel in a single layer keeping a tight contact with the threads until there’s about 2cm or so left.

- Then I tape down all of the nichrome on the barrel, except the last 2cm.

- I untape the part of the nichrome on the nozzle.

- As I was out of those little metal connectors provided by MakerBot, I had to improvise a little.

- I stripped the leads on the nichrome so that about 3mm was exposed and used needle nose pliers to put it into a hook shape.

- Then I stripped the leads to the insulated wires so that about 15mm was exposed, used my fingers to twist the leads, doubled it back along itself, twisted it again so that there was a little loop.

- I hooked the nichrome into the loops of braided copper leads and crimped it down using the needle nosed pliers.

- Solder and done.

- I then liberally applied kapton to wrap the barrel and nichrome so that it would be unlikely the wire or leads would ever have to bear any of the stress should I move the extruder around.

- With my last two extruder assemblies I’ve taken a slightly different approach to attaching the thermistor. This method makes it easier to pull the thermistor out, but slightly more difficult to install it in the first place. Here’s what I do:

- I laminate the thermistor between two layers of kapton tape just past where it meets the insulated wires. Only the very tip of the thermistor is exposed.

- I wrap the barrel in nichrome as above, then ceramic tape, then wrap that in kapton – without the thermistor inside.

- Once the entire barrel is wrapped up just as I want it, I use a utility knife to make a vertical slice up the ceramic tape starting at the edge of the nozzle until I reach the point where the nozzle meets the barrel.

- I then peel back the ceramic tape and kapton, exposing a V shaped portion of the nozzle.

- I put the tip of the thermistor down into the V, replace the ceramic tape and kapton over it, and tape it down.

- I then re-wrap the barrel in kapton again.

- The first time I disassembled my extruder I screwed up my thermistor when unwrapping the barrel. While this makes it more difficult to get the thermistor into the assembly, it also makes it so much easier to pull it out and reuse it.

- At the top left of the above photo you can see a small black box with green and white wires coming out of it. That’s where I added an ethernet jack connector to the extruder assembly to make it easier to connect/disconnect the extruder.

- When I assembled my MakerBot I used insulated wire out of an ethernet cable. Since I only needed a few sets of insulated wire, I ended up with one piece of ethernet cable that still had the ethernet jack on it with four wires sticking out. I also had two ethernet ports left over from my opto-endstop kits.

- I plugged the ethernet jack into the ethernet port and tested the leads on the wires against the leads on the port. Once isolated I soldered wires to the four leads that lead to the four wires from the jack.

- I then soldered the four wires from the ethernet jack to the thermistor and nichrome.

- I took the wires I soldered to the ethernet port and ran them through the hole on the right side of the MakerBot in the back on the top. Then connected those leads to the appropriate ports on the extruder board.

- Once the wires were soldered up and extruder assembled I plugged the ethernet jack into the ethernet port and checked ReplicatorG to see if I could get a thermistor reading (yes) and heat the barrel (yes).

As I tinker and modify my MakerBot it seems I’m moving towards a system where I try to make the extruder assembly as modular as possible. I didn’t have this as a conscious thought when I started, but that’s where these modifications have been headed. While it is very convenient to have a totally modular extruder only connected to the robot by four bolts and an ethernet cable, that system is most useful if you are using drastically different print heads (such as a frostruder, Paxtruder, Bowden extruder, etc).

If you’re just swapping between PLA, ABS, or other plastic filament or color variations thereof, you can reuse the vast majority of the extruder assembly – the board, the motor, and the entire acrylic plastruder. If you had a different heater assembly you could just undo the two screws that attach the heater to the extruder, disconnect the thermistor, disconnect the nichrome, and swap in a new set. Although I don’t have a fully assembled second heater section yet, this set up makes a lot of sense to me just for ease of maintenance and repair.

- While I sing Christmas carols with my friends Meryl and Cheryl. [↩]

He’s saying the things I think!

…only in a way that is far less wordy and verbose than the manner in which I would typically attempt to describe the sorts of things I am thinking about.

“”The way you improve your iPad isn’t to figure out how it works and making it better. The way you improve the iPad is to buy iApps. Buying an iPad for your kids isn’t a means of jump-starting the realization that the world is yours to take apart and reassemble; it’s a way of telling your offspring that even changing the batteries is something you have to leave to the professionals.”

This is part of what is at the core of the Maker philosophy – empowering people to learn about the stuff of which civilizations are made, rather than being a plankton-like consumer/spectator. When something goes wrong, you don’t have to take it back to the store or call the (*shudder*) Geek Squad. 1

This is the heart of civilization, improving upon the work of prior generations. You have the luxury of being smarter than Einstein and wiser than Oppenheimer with 20-20 hindsight. You can know everything they know and improve upon it all. You can fix it yourself. 2 You have all of the tools you need right now, in your home right now. You can use the stuff you already have to build the tools you need to build absolutely anything within imagination.

I don’t think I’m THIS enthusastic about anything

Which means, depending on how you look at things, this is either a commentary on how nutty some people can be or how empty my life is. 1 Here’s a comment from a woman who purchased an iPad:2

“Have you touched one?” she said after being asked why she showed up at 7:30 a.m. at the Apple store. “It’s going to change everything about how you live. You are going to be connected to everything. You are 30 seconds away from anything you need to know. It’s really amazing.”

This quote makes it sound as if by purchasing an iPad the sky will open up and the Dali Lama will start IM’ing you for advice about life, the universe, and everything. I like Apple, I like Apple products, and I love how they’ve raised the bar as to what we expect from computers3 , portable music devices, and mobile phones. That said, they did not invent the internet when they launched the iPad. 4 I’ve been 30 seconds away from anything I needed to know the day I got my first web-enabled phone.5

A RepRap business model

So, here’s an idea – much like the distributed manufacturing system for printed pulleys, why doesn’t someone set up a website business for RepRap parts? Here’s the outline of the business plan:

- A price could be set for a particular RepRap plastic part, depending upon size, complexity, scarcity, how many more are needed to make a full set, etc.

- People with RepRaps/Straps can register for an account and send in RepRap parts, and get their account credited for those parts.

- Ideally, the website would also have an area where you can print out a table of contents – with bar codes. That way the receiver could just scan the parts into their inventory – and verify the contents/quality later.

- People who send in parts are paid on a regular basis electronically.

- The site also contains a store where you can purchase an entire set of printed/molded RepRap parts – or perhaps just those ones you need.

- It would be quite handy if such a site also sold the various other parts needed for a RepRap – bearings, metal rods, electronics, fasteners, etc.

- I suppose the sets could be sold on a bid-style basis – and the parts paid for pro-rata. 1

This idea isn’t without it’s problems:

- How do you ensure a minimum quality in crowdsourced parts?

- Perhaps you could use a seller/rating system like BrickLink does for lego vendors?

- Why would someone buy/sell from a website like this rather than eBay?

- Well, eBay and Etsy each take about 3.5% with PayPal snagging another 3% or so. Assuming sales are handled through PayPal2 , you’re talking about basically 6.5% out of the seller’s end.

- Assuming you go with PayPal (3%) and you charge less than the 3.5% for eBay, you can probably attract buyers and sellers. The problem is once you’ve gotten this far, you’ve basically re-created eBay buy-it-now or an Etsy store. To succeed you’ll need to serve the market better or cheaper.

- As soon as RepRaps in the wild increase or demand for parts is met, won’t the bottom drop out?

- Quite possibly. A week ago Mendel plastic parts were selling for $450. 3 Today it looks like parts are going for about $300 or so. Then again, a set didn’t sell with a $200 reserve just a few days ago.

- How many sets have been sold on eBay anyhow? A dozen? Let’s say it was 20 sets at $450 each. 20 * $450 * 3.5% is $315.00. If 100 sets are sold at $300 with a 3.5% cut, that’s $1050. Neither of these amounts would not have been enough to entice me to code a RepRap sales site – but I’m a slow coder.

$100 CNC mill?

I caught sight of this through Spacexula‘s RepRap Aggregator Feed – a $100 open source CNC mill. I was just thinking the other day how cool it would be to have an additive and subtractive CNC machine sitting next to one another.

But, $100?! It’s like someone would be paying me to build the thing.

So what are you going to make?

I remember the first time I heard this question. I was babbling to a friend of mine about how I wanted a MakerBot. His response was to ask:

What is it you need that you want to spend $1,000 getting?

My first inclination when I hear this question to say, “Anything.”1

My second inclination is to step back, think about it for a moment, and then wonder whether I am going to ever actually print $1,000.00 worth of stuff. 2

Thanks to Jeff Keegan for unintentionally reminding me to post this. :) 3

- Sometimes I’m tempted to respond, “Anything I damn well want, Nosy Noserton.” [↩]

- Although, at this point, it would be closer to $1,250 of stuff… [↩]

- That bastard. [↩]