Is that I tend to think up better ideas about what I want to build with my ‘bot. Seriously, the downtime is quite useful that way.

Month: February 2010

Am I taking this too far?

You guys are going to have to let me know if this whole “Polly/PLA” and “Abby/ABS” thing starts to get creepy. Ferris Bueller famously once said… “You can never go too far.” As far as I know, anyone who’s ever taken Ferris’s advice ended up just fine.

I’m tempted to explain the references, but I don’t want to kill the joke…

Dear Polly – I can’t believe I’m writing to you again…

My friends are telling me to give you another chance. They say you’re not so bad, that if I just put in the time things will work out. They say you’re capable of being faithful too…

Maybe there was just too much pressure on our relationship. Heaven knows we let things get too heated sometimes.

Was I expecting too much from you? I thought everything would be magic and come out smelling like roses. Things seemed to work fine at first, but they quickly turned into a big gooey mess.

Polly, I’m so confused. After all we’ve been through, I get all choked up… I just don’t know how I can take you back so soon. And, well, Abby has always been there for me… 1

Truly,

MakerBlock

- Well, for the month and half I’ve had my MakerBot… [↩]

An idea for checking the temperature of an extruder at the barrel entry

Several people have suggested that the temperature at the entry of the barrel is very important to printing with PLA. This makes sense. If the temperature at the barrel entry is above the melting point for PLA, it can melt right there and ooze down around the threads.

Maybe I should assembly my extruder with just the thermistor on the barrel entry, and heat it until it is just below the melting point of PLA – then check the temperature at the nozzle.

Or, I could get a second thermistor and use it at the top of the barrel while keeping the original thermistor at the nozzle. I could only use one set at a time (since I don’t know how to hack the electronics/extruder board), but that shouldn’t be an issue.

MakerBot extruder clog experiment

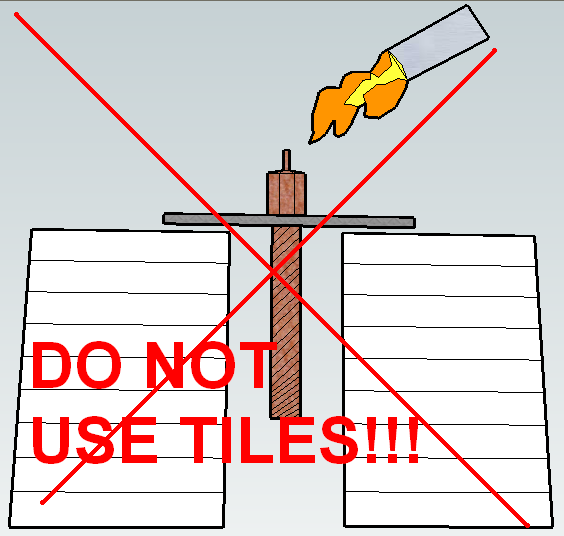

UPDATE: DO NOT USE TILES!!! THEY WILL SHATTER! READ LATEST POST!

The bad news is this is my first clogged extruder. The good news is I have all the spare parts to whip up a new extruder, no problem. That means I can experiment with wild abandon! My backup plan is to slice and dice the PTFE insulator into washers.

Having drilled out most of the plastic clog from the barrel, it’s mostly empty. The PTFE is in pretty good shape with the threads intact, if a little worse for wear. My plan to get the remaining plastic out of the nozzle is to put the nozzle/barrel assembly into the large washer upside down and prop it up on some ceramic tiles.

My hope is that by applying a heat source to the nozzle the plastic will just drip/fall out. The suggestion for using a blow torch to clear out the barrel and nozzle comes from Rick Pollack / MakerGear. Thanks again Rick!

By the way, wicked Google Sketchup skillz, no?

Leonardo Robot

Freaking cool. This robot was designed by jrombosky by taking the measurements/proportions/ratios from Leonardo DaVinci’s Virtuvian Man. Even if these proportions were all messed up, this would still be super awesome. It’s a little printable robot!!!

It reminds me of a lego set from a few years ago:

Plastic oozing into threads – is that the end of my insulator?

I don’t know, but I’m about to find out.

I’ve managed to clear out the PTFE insulator pretty well. I pulled the entire heater out of the extruder, turned up the heat a little, held the barrel lightly in plyers, and unscrewed the PTFE without a problem, and then turned the heat off. I then used a precision flathead screwdriver to follow the threads, popping/chipping the plastic out as I followed I went. However, I don’t know to what extent the threads are still intact. Since the PLA oozed into the threads, I have to think they’re messed up to some extent.

As for the barrel, I used a drill bit with the unsharp end wrapped in a rubber band. I rotated the bit using the rubber band as a grip to drill out the plastic. It actually worked really well for clearing out the barrel right to where I can see the barrel entering the nozzle. The inside is reasonably clean, but I still can’t put a filament into it freely.

I also had to take a precision screwdriver and follow along the threads on the barrel to chip out plastic. This went reasonably quickly. Once I was done the nut was able to screw on and off freely.

Now I’m left with a slightly discolored PTFE and a mostly clean barrel. I’ve got a spare PTFE insulator, but I’m hoping this one is salvageable. It still has threads and the barrel will screw in nicely.

Rick and Spacexula have suggested I use a torch to heat up the nozzle and let the plastic burn/fall out. But, this is a trick for another day with proper safety equipment.

Oh, and before I forget, Spacexula suggested keeping a ruined PTFE barrier to slice into insulating washers. I’m hoping I might be able to re-use the PTFE insulator, but this is certainly my backup plan.

Dear Abby

I’m so sorry – I don’t know what I was thinking. I must have lost my mind. Polly meant nothing to me.

The little things just always seemed to work out between us. Sure, we had our rough patches when it came to larger things, but we learned to live with that.

You were faithful and I let you go. Abby, please take me back. 1

Yours forever more,

MakerBlock

- ABS – Acrylonitrile butadiene styrene [↩]

PLA Woes

My adventure with PLA has ended in heartbreak. It wasn’t working very well so I switched back to ABS – which was fine for a few prints. Until I found it just wasn’t extruding and stripping the filament.

So, disassemble time. My filament looked like it was getting shoved into a jam and splitting apart like a banana – with the center making it down to the nozzle through a small aperture. I found I couldn’t remove the insulator – and upon looking closer found that a very small amount of PLA had oozed down and around the nut above the insulator/ washer. I removed the extruder assembly from the ‘bot, and the heater assembly from the extruder, heated it back up and slowly removed the PTFE insulator. I found the barrel was clogged with ABS as was the insulator.

I’ve managed to clean out most of the insulator, the nut, and the threads of the barrel using drill bits and precision screwdrivers.

I’m going back to ABS, I would rather deal with warp than the heartbreak of PLA ooze into the threads of my heater assembly.