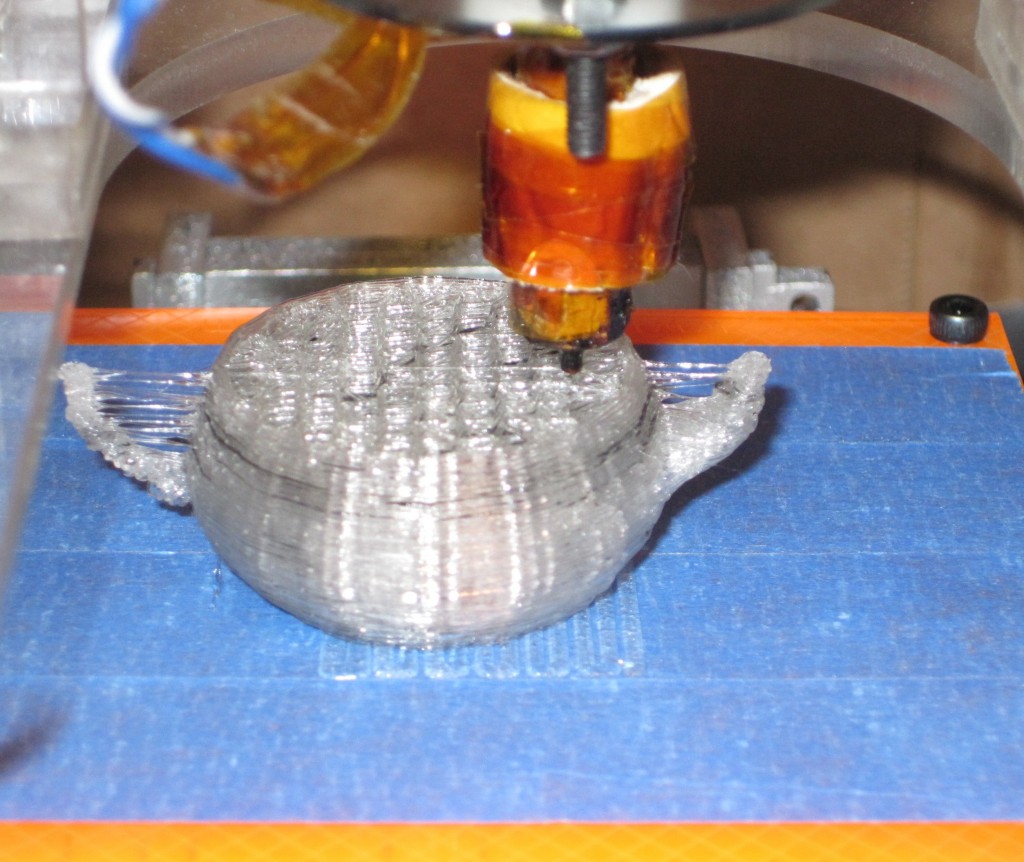

Not really a problem after all. I’m printing up a (well, another) teapot right now. Having just run the PLA through rather than trying to actually remove the ABS the teapot has these black streaks throughout. I kinda like it.

Month: February 2010

PLA success?!

I figured, what the hell – I built it and I can (probably) repair it, right?

So, I backed out the black ABS I have been printing in, jammed in some freaking sweet PLA, ramped up the heat on the extruder to the exact settings I use for ABS, and then FIRE THE MAKERBOT!

For comparison’s sake I used the same exact settings, same exact Gcode file from the last single walled test piece.

What did it look like, pray tell?

I thought you’d never ask.

MakerBot, Mendel, Mendel-Mini Build Areas

Owning a MakerBot, I’m not even sure why someone would need something to print pieces much larger than the MakerBot build area. Printing something as large as just the maximum build volume of a MakerBot would take ages.

- Darwin’s build area is about 23cm x 23cm x 10cm: 5290 cubic centimeters

- Mendel’s build area is about20cm x 20cm x 14cm: 5600 cubic centimeters

- Cupcake CNC’s build area is 10cm x 10cm 13cm: 1300 cubic centimeters

- Mendel Mini’s is supposedly approximately 11cm x 14cm x 10cm: 1540 cubic centimeters

While the official longest print logged on the Makerbot website is Zach’s Disney head, clocking in at 2 hours and 45 minutes, I’ve read about people printing for up to 8 continuous hours. If the build volume for a Mendel is 4.3 times that of a Makerbot, it would take more than 34 hours to fill that build area.

When you’re printing a door hook in 15 minutes, it doesn’t pay to drive to the hardware store. When it takes 34 hours to print a big plastic brick, you’re better off driving to the gas station, filling up your tank, driving to McDonald’s, filling out an application, working an hour, quitting and demanding your paycheck, driving to the hardware store, buying a single brick, and then driving back home. I figure that kind of silliness would only take half a day or so. Heck, with 34 hours, you could do this at least six times over.

Mendel Mini

I’m voting for the Mendel Mini because:

- Quicker to print

- Less plastic

- Can still self-replicate

- Can still create the parts for a full Mendel

Mendel or Mini-Mendel

Which would you rather have?

Skeinforge tuning guide

Nick Ames has posted a very thorough guide to tuning Skeinforge.

There are some things I like about this guide – such as he suggests keeping extruder speed and platform speed maxed. ;)

I’ll print something up with my current settings, zip those, and then trying this guide out.

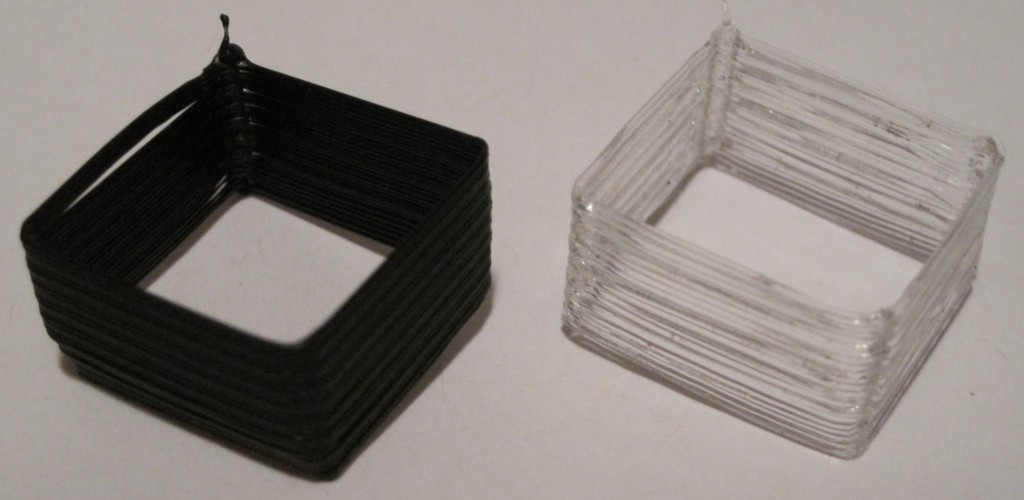

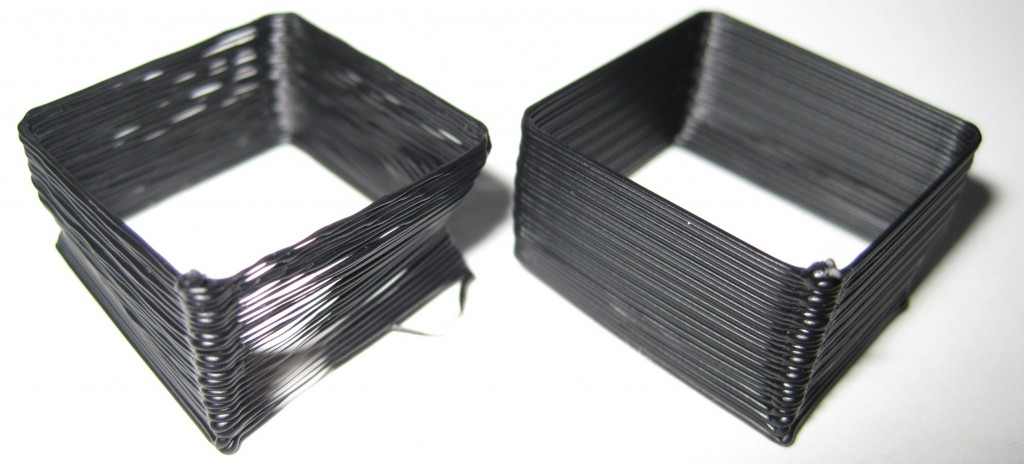

Skeinforge calibration test 1, 2

For these tests I used the “single walled test piece” from Da3v

- Test 1 on the left

- Temperature: 220

- Skeinforge -> Carve -> Layer Thickness (mm): 0.36

- Skeinforge -> Speed -> Flowrate PWM Setting (if PWM Setting is Chosen): 230

- Skeinforge -> Speed -> Feedrate (mm/s): 40

- Skeinforge -> Speed -> Travel Feedrate (mm/s): 40

- Extrusion diameter: 0.57

- Skeinforge -> Speed -> Extrusion Diameter Over Thickness (ratio): 1.583

- Wall thickness of the test piece: 0.40

- Test 2 on the right

- Skeinforge -> Speed -> Feedrate (mm/s): 30

- Skeinforge -> Speed -> Travel Feedrate (mm/s): 30

- Wall thickness of the test piece: 0.40

- Skeinforge -> Speed -> Extrusion Diameter Over Thickness (ratio): 1.583

- Skeinforge -> Carve -> Extrusion Width over Thickness (ratio): 1.583

- Skeinforge -> Inset -> Extrusion Perimeter Width over Thickness (ratio): 1.583

That’s a pretty big improvement. I haven’t tried printing something small with lots of details, but now I’m curious how well these settings hold up. My previous settings (which I zipped in case I totally messed this up) were reasonably good, but the layer adhesion was merely adequate.

Dragging my feet on PLA

I’ve been a total slacker about getting started printing in PLA. Part of the reason is I’ve seen others have a lot of problems printing with it – ruining extruders, oozing out of barriers, too hot, too cold, too just right, the heat is uneven, the barrel jams, etc, etc. However, since I’ve been printing larger and larger objects I’m finding that warpage is become more of an issue. This means I need to either buy/make a heated platform for the ABS or I need to switch to PLA.

There’s a few things I’d like to build that are big and flat. I’d like to print up a modular chess board (already have it designed in my head, I just need to export it to Sketchup) and crank out a few Mendel or Mini Mendel pieces.

Default Series TitleHow to caliberate and tune Skeinforge for your MakerBot

Update 4/21/2011: This post is more than a year old. Since then I’ve created ProfileMaker which should eliminate the need for almost all of these steps. Share and enjoy!

A MakerBot Operators group member, Cliff Biffle, has posted a very comprehensive list his Skeinforge tuning and calibration procedure. Cliff owns MakerBot #69 from Batch#4, named Kallisti. Although Cliff has a MakerBot Skeinforge tuning page, it looks like he hasn’t had a chance to transcribe his lab notebook yet. However, Cliff has been patient enough to type up his Skeinforge calibration information twice for the benefit of the MakerBot Operators group. Here are links to his original postings on 1/6/2010 and another on 1/15/2010.

The other day I wanted to go back and find his calibration procedure, but had forgotten who had posted it, when it was posted, and which thread it was posted. Having now found it, I don’t want to lose it again. It turns out that Cliff had posted it once in response to my own question about dialing in Skeinforge settings in order to print up lego pieces! Thanks Cliff!

I’ve mashed his two posts together to put together this checklist:

- Adjust Temperature: Skeinforge -> Raft

- Find a temperature that allows you to extrude quickly and easily without too much popping or smoking

- MakerBlock: I have one of the 1mm thermistors, use the Zach 1 temperature table, and print reliably at 220

- Adjust Layer Height: Skeinforge -> Carve -> Layer Thickness (mm)

- Cliff uses the default of 0.36

- Adjust Extrusion Speed: Skeinforge -> Speed -> Flowrate PWM Setting (if PWM Setting is Chosen)

- Make the extruder go slower and lower the PWM value

- Cliff uses 230

- Adjust Feedrate: Skeinforge -> Speed -> Feedrate (mm/s)

- Too fast and you lose the fine detail and introduce errors. Too slow and it will be too… slow.

- Rick Pollack of MakerGear suggests setting Skeinforge -> Speed -> Feedrate (mm/s) and Skeinforge -> Speed -> Travel Feedrate (mm/s) to the same figure between 20 and 45

- Too fast and you lose the fine detail and introduce errors. Too slow and it will be too… slow.

- Adjust Skeinforge to understand how much plastic is being extruded

- Raise the Z axis and perform a test extrusion into the air

- Do not pull or stretch the extrusion

- Using calipers, measure its diameter, D

- Go into Skeinforge and look up the configured layer thickness, T, from Skeinforge -> Carve -> Layer Thickness (mm)

- Divide the diameter by the thickness, D/T

- Set Skeinforge -> Speed -> Extrusion Diameter Over Thickness (ratio) to D/T

- Print a test piece with thin walls

- Measure the width, W, of a single extrusion somewhere above the first few layers

- Divide the width by the thickness, W/T

- Set Skeinforge -> Carve -> Extrusion Width Over Thickness (ratio) to W/T

- Cliff said this setting may be in Fill, but I think he may have meant Carve

- Nick Ames has suggested setting Skeinforge -> Carve –> Extrusion Width over Thickness (ratio), Skeinforge -> Inset -> Extrusion Perimeter Width over Thickness (ratio), and Skeinforge -> Speed -> Extrusion Diameter over Thickness (ratio) all to the same value. His post also has a lot of information and links about other potential Skeinforge tuning resources.

- Adjust other Skeinforge settings

- Overlap of grid corners

- Infill density

- Unpause

- Stretch

Replicators

Did I ever mention I have already printed up a MakerBot version of a Stargate SG-1 “Replicator” cell? Well, I did. I basically “borrowed” someone’s Sketchup file from the google 3D warehouse, saved to STL, and printed it up!

In any case, it made me think of a cool T-shirt idea. The back side of the shirt would have a Stargate Replicator with a red circle slash over it, labeled “Bad Replicator.” The front could have a picture of a ‘bot saying “Good Replicator.”

I’d wear it.