I figured, what the hell – I built it and I can (probably) repair it, right?

So, I backed out the black ABS I have been printing in, jammed in some freaking sweet PLA, ramped up the heat on the extruder to the exact settings I use for ABS, and then FIRE THE MAKERBOT!

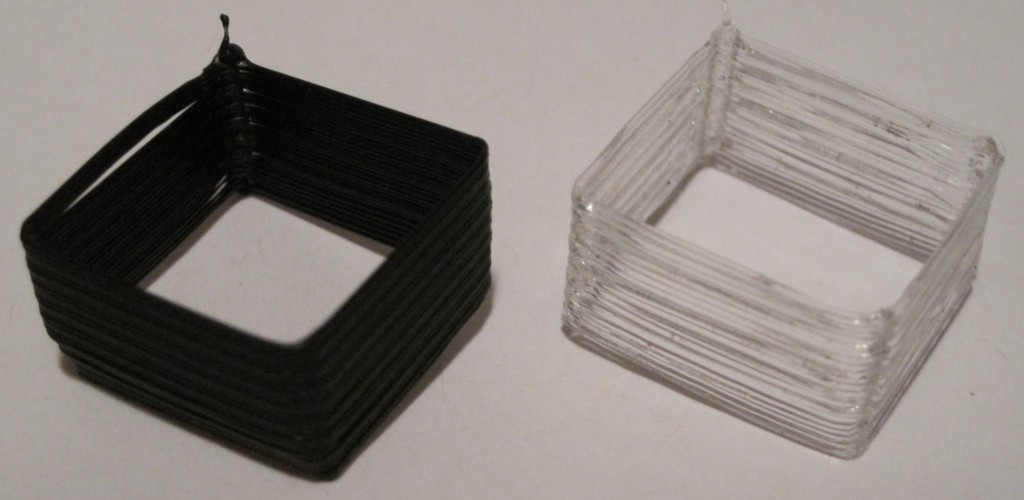

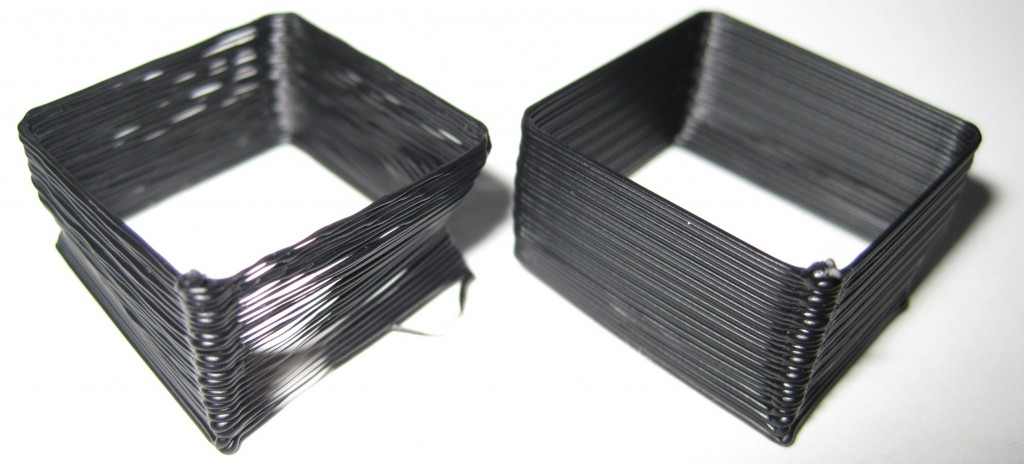

For comparison’s sake I used the same exact settings, same exact Gcode file from the last single walled test piece.

What did it look like, pray tell?

I thought you’d never ask.