SWEET. I’ve been so busy of late123 that I haven’t even been able to print several of the things I’ve uploaded. I’ve uploaded several cookie cutters, with another sitting on my hard drive and one more knocking about in my head keeping the cobwebs company. I’ve also uploaded my variation on a simplified Rubik’s cube.

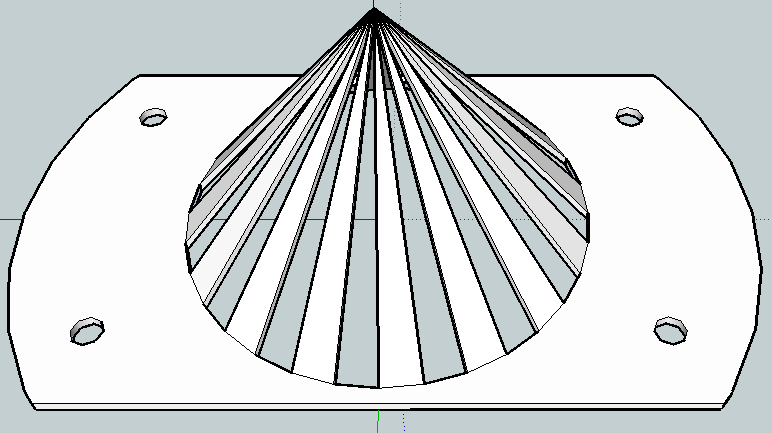

Well, someone printed it! It looks AMAZING! I wonder if it works properly? I slapped the design together rather hastily after getting frustrated with my MakerBot failing to print TomZ’s 1x2x3 Rubik’s cube.4

I can’t wait to either get some feedback from Lotu (who printed it) or print up one of my own so I can improve on the design. I’d really like to make a version that is 100% printed – with a snap joint in the middle rather than a nut/bolt system. If I go down that route, I was thinking about incorporating what I learned from the fantastic Becco blocks connection system by r3becca.

If you print one of these, please answer the following questions:

- Which STL did you use? The one with all 6 pieces or the one with 3? Would you prefer printing the pieces one at a time?

- How well did they fit together? Are they very snug? Too loose?

- How well does the nut/bolt work?

- Did you have to adjust your Skeinforge settings at all? Why? How?

- Do you have giant hex wrenches like Lotu does?

- Mostly writing nonsense. [↩]

- Which is particularly funny since my day job consists almost entirely of writing. [↩]

- Which is even funnier when you consider that you can tell I’m doing a particularly good job when my writing is completely incomprehensible. [↩]

- Did you catch how I swapped all the numbers around to differentiate my derivative? I thought that was pretty clever… [↩]