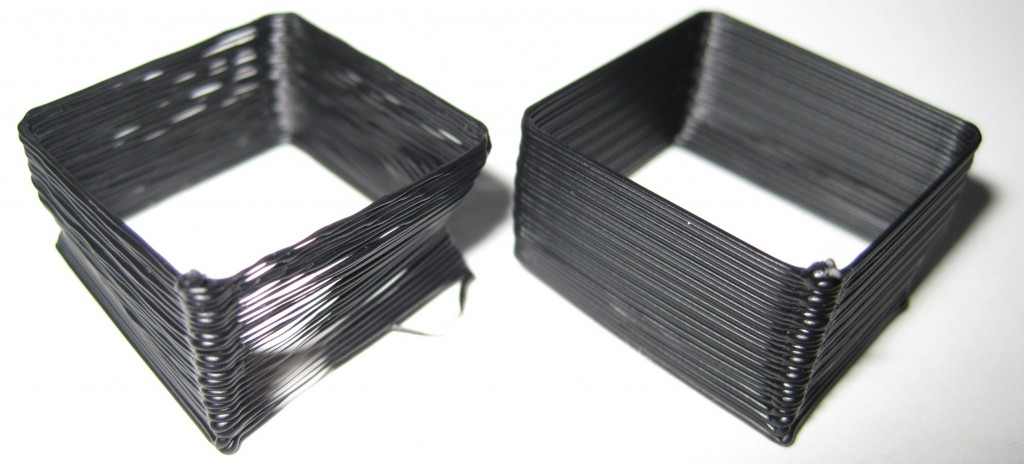

For these tests I used the “single walled test piece” from Da3v

- Test 1 on the left

- Temperature: 220

- Skeinforge -> Carve -> Layer Thickness (mm): 0.36

- Skeinforge -> Speed -> Flowrate PWM Setting (if PWM Setting is Chosen): 230

- Skeinforge -> Speed -> Feedrate (mm/s): 40

- Skeinforge -> Speed -> Travel Feedrate (mm/s): 40

- Extrusion diameter: 0.57

- Skeinforge -> Speed -> Extrusion Diameter Over Thickness (ratio): 1.583

- Wall thickness of the test piece: 0.40

- Test 2 on the right

- Skeinforge -> Speed -> Feedrate (mm/s): 30

- Skeinforge -> Speed -> Travel Feedrate (mm/s): 30

- Wall thickness of the test piece: 0.40

- Skeinforge -> Speed -> Extrusion Diameter Over Thickness (ratio): 1.583

- Skeinforge -> Carve -> Extrusion Width over Thickness (ratio): 1.583

- Skeinforge -> Inset -> Extrusion Perimeter Width over Thickness (ratio): 1.583

That’s a pretty big improvement. I haven’t tried printing something small with lots of details, but now I’m curious how well these settings hold up. My previous settings (which I zipped in case I totally messed this up) were reasonably good, but the layer adhesion was merely adequate.