After about half an hour I noticed my drawing robot was not making the low scritchy scratchy humming drawing noise. I’ve started the drawing again… It looked like it should have been working, the controller software indicated it was still connected, the command queue was still loaded, the Arduino + Motor Shield were still lit up, but it just wasn’t moving.

In retrospect, I should just have hit the reset button on the Arduino. I think that would have made it pick up with the last command. But, then I wouldn’t have the lovely picture above to show you!

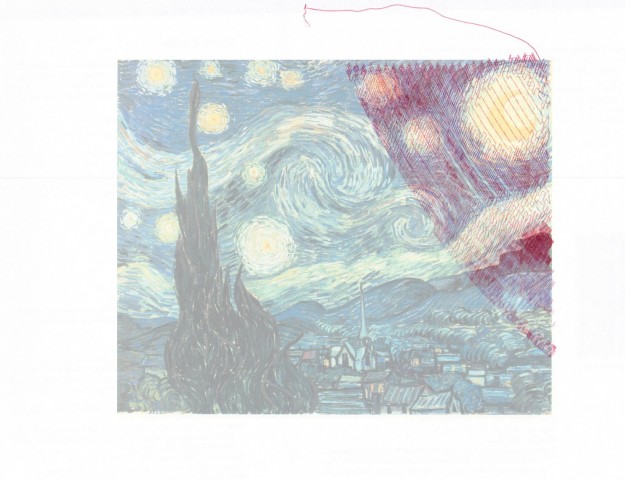

Actually, I’m really really happy with the drawing quality. Check out what it looks like when overlaid the subject image: