Building my MakerBot and getting it printing reliably was challenging, but totally doable by a technical novice such as myself. I have lots of people on the MakerBot Operators group to thank for their patience and help in getting my MakerBot online. Looking back, I spent about a month building and then calibrating my ‘bot.

It’s easy for me to forget that first month of occasional frustrations and triumphant victories, now that I’ve been printing successfully for more than eight months. It actually makes me a little sad when I read people writing about their own frustrations and how they’re ready to throw in the towel. The most recent example was noobcake getting frustrated with her ‘bot and getting ready to sell it off in parts. Thankfully, Spacexula swooped in to help her out.

This brings me to We Alone On Earth‘s recent post. WAOE are a group of introspective, philosophically and technologically minded twenty-somethings. To give you you an idea of their frustration with their ‘bot, the post was entitled, “MakerBot: not very much fun at the moment (caveat emptor)” Yikes. I realize that WAOE has revised their original post several times since the original publishing date – but they have a lot of legitimate concerns.

WAOE list off seven problems with the MakerBot. I’m not going to refute these points – but rather offer another perspective on them. After several updates, WAOE offer additional comments, I’ll include them here in “[]”.

- The PTFE is prone to melting. [WAOE expects the new MK5 Plastruder will resolve this issue]. I have never heard of a PTFE barrier melting. I’ve heard of them deforming from a blockage and had one develop a clog which I had to remove. Several people have purchased MakerGear PEEK replacements – but these are far from necessary. I clogged my first barrier once, cleared it, clogged it again, and am now using a slice of it as an insulating washer.

- Inexplicable printing behavior due to noise. [WAOE fixed this issue by twisting wires and installing a resistor]. I’ve never had this problem, but I know others have. Like WAOE, I’ve heard of people fixing these issues by twisting wires, using resistors, or ferrite beads. Perhaps my workstation has less electronic noise, but I haven’t had to do any of these things. Then again, perhaps my prints suffer from a certain degree of noise?

- Printing large objects is hard without a heated build plate. [WAOE notes this isn’t an issue if you’re good at soldering]. Totally true for ABS, but not PLA. However, this is really a problem with the print media – not with the printer, right? ABS will warp as it cools, unfortunate but true. I’ve had less warping problems in warm weather or during with a second print – basically when the build platform is already warmed up. Zaggo’s printruder is one of the largest things I’ve printed. Interestingly, his design takes into account that certain parts are expected to warp. Or check out Clothbot’s train track – it was designed with a lattice/correlated bottom to prevent warp problems. Plastic warps – but with careful and thoughtful designing, this shouldn’t be a limitation.

- The heated build platform is difficult to build and requires a relay kit. [WAOE notes this isn’t an issue if you’re good at soldering]. I can’t dispute either point. I just got both and haven’t had a chance to assemble them yet. I’m assuming the heated build platform, which requires SMT soldering, will be challenging. Frankly, fear of SMT soldering was the big reason why I didn’t jump into buying a MakerBot sooner. The MakerBot HBP is just one option for a heated platform – there’s several others out there. Don’t like SMT soldering? Try out Rick’s platform over at MakerGear. More into DIY? Well, use the plans posted for any of several other variations. As for the relay kit – it’s not a requirement – but it will prevent MOFSETs from burning out on your extruder motherboard.

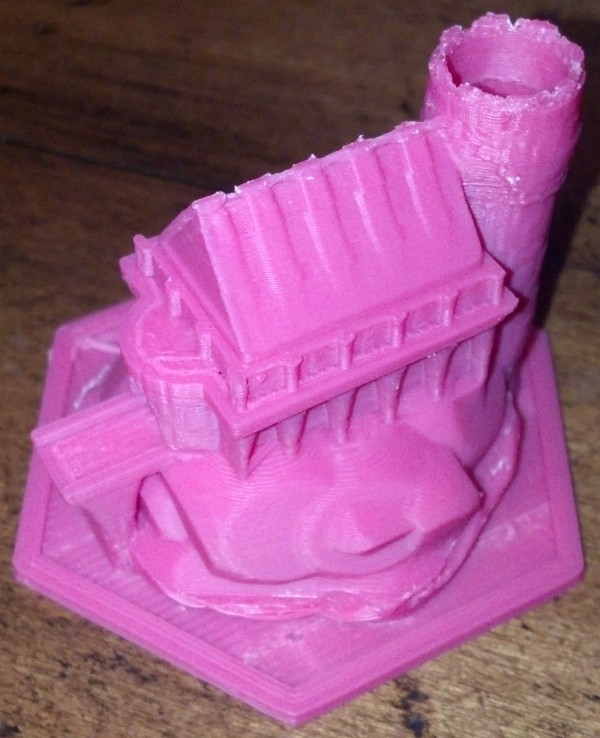

- Calibrating Skeinforge is hard. [WAOE notes this is still an issue]. I like to use the word, “challenging.” A better way to look at MakerBot calibration is that you get out of it what you put into it. I have my MakerBot tuned to the point that I get reasonably good looking durable parts. Sure, I could spend more time and get even better looking parts. However, once I got it printing reliably I was much more interested in printing new things than refining the printing process. I’ll get around to improving the print quality even more – but I’m having too much fun right now.

- The Plastruder MK4 feed system is unreliable. [WAOE expects the new MK5 Plastruder will resolve this issue]. Getting the tension on the MK4 idler wheel is just one of those aspects of my MakerBot I had to experiment with and get just right. I’ve been printing reliably for eight months using the same idler wheel and gear. With proper maintenance, flossing the extruder, and clearing chips out of the extruder the current setup is serving me well.

- The threaded rods are of poor quality. [WAOE are getting new threaded rods, which should fix their problem.]. Of my four threaded rods, one is definitely warped and two have very minor warps. By experimenting, rotating them just so, and printing a few wobble arrestors I’ve eliminated most of these issues. You can definitely get more expensive and straighter threaded rods and improve your build quality.

A MakerBot Cupcake CNC kit is not for everyone – but the kit can be build and operated by anyone who is willing to invest the time to do so. It is a cheap, hackable machine that is literally going to be just as useful as you make it. Want less warpage, higher resolution, more reliable extrusion? You can buy an upgrade, build one from their plans, or design your own solution. Want a CNC mill, CNC pencil, or CNC music box? Design the very first one! Then again, you don’t have to do any of these things.

A MakerBot kit is just a platform for your creativity. It’s just that big.

As for you, WAOE, if you want some help – drop me a line!