… or Happy Zombie Day!

My extruder is back online! Huzzah! Since I had it disassembled I made a few minor modifications.

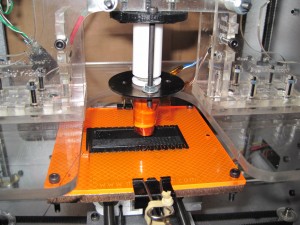

- I’ve added binder clips to the front and back edges of the build platform. I found that my acrylic build base is slightly deformed and probably getting more so with each build. This is a temporary fix while I get around to picking up a new build base.

- You’ll notice I’ve also added pieces of rubber band. I cut a long rubber band into two pieces about an inch long, tied them off to make small loops, and put them around the handles to the binder clips. I don’t want to take the handles out of the binder clips because then they’ll be difficult to move/remove/replace. But, as I printed they tended to vibrate creating unnecessary noise.

- When ABS oozed down my PTFE threads and around the barrel, I sliced off about 1mm to use as a washer between the nut and large washer. The reason I’ve heard suggested for the PTFE washer is that it keeps the large metal washer from acting as a heat sink. The nut is right on the barrel and is able to heat right up along with the rest of the barrel. When the large washer is pressed on the nut (as it is supposed to) it is able to absorb heat through the nut as well as it’s contacts to the barrel. The thin surface area contact between interior hole in the large washer and the barrel probably doesn’t allow for much heat to be transferred to the large washer.

- I’ve read it mentioned that wrapping an extruder with nichrome is a two person or three handed job. I’ve found it to be fairly easy with just my two hands.

- I use a small piece of kapton to tape the nichrome to the extruder head/nozzle oriented so that it is lined up parallel to the barrel. 1

- From the point where I can see the nozzle touch the barrel I leave about 2-3cm of nichrome hanging off the edge, with the rest of the nichrome pointed up towards the barrel.

- Then I wrap the nichrome up the barrel in a single layer keeping a tight contact with the threads until there’s about 2cm or so left.

- Then I tape down all of the nichrome on the barrel, except the last 2cm.

- I untape the part of the nichrome on the nozzle.

- As I was out of those little metal connectors provided by MakerBot, I had to improvise a little.

- I stripped the leads on the nichrome so that about 3mm was exposed and used needle nose pliers to put it into a hook shape.

- Then I stripped the leads to the insulated wires so that about 15mm was exposed, used my fingers to twist the leads, doubled it back along itself, twisted it again so that there was a little loop.

- I hooked the nichrome into the loops of braided copper leads and crimped it down using the needle nosed pliers.

- Solder and done.

- I then liberally applied kapton to wrap the barrel and nichrome so that it would be unlikely the wire or leads would ever have to bear any of the stress should I move the extruder around.

- With my last two extruder assemblies I’ve taken a slightly different approach to attaching the thermistor. This method makes it easier to pull the thermistor out, but slightly more difficult to install it in the first place. Here’s what I do:

- I laminate the thermistor between two layers of kapton tape just past where it meets the insulated wires. Only the very tip of the thermistor is exposed.

- I wrap the barrel in nichrome as above, then ceramic tape, then wrap that in kapton – without the thermistor inside.

- Once the entire barrel is wrapped up just as I want it, I use a utility knife to make a vertical slice up the ceramic tape starting at the edge of the nozzle until I reach the point where the nozzle meets the barrel.

- I then peel back the ceramic tape and kapton, exposing a V shaped portion of the nozzle.

- I put the tip of the thermistor down into the V, replace the ceramic tape and kapton over it, and tape it down.

- I then re-wrap the barrel in kapton again.

- The first time I disassembled my extruder I screwed up my thermistor when unwrapping the barrel. While this makes it more difficult to get the thermistor into the assembly, it also makes it so much easier to pull it out and reuse it.

- At the top left of the above photo you can see a small black box with green and white wires coming out of it. That’s where I added an ethernet jack connector to the extruder assembly to make it easier to connect/disconnect the extruder.

- When I assembled my MakerBot I used insulated wire out of an ethernet cable. Since I only needed a few sets of insulated wire, I ended up with one piece of ethernet cable that still had the ethernet jack on it with four wires sticking out. I also had two ethernet ports left over from my opto-endstop kits.

- I plugged the ethernet jack into the ethernet port and tested the leads on the wires against the leads on the port. Once isolated I soldered wires to the four leads that lead to the four wires from the jack.

- I then soldered the four wires from the ethernet jack to the thermistor and nichrome.

- I took the wires I soldered to the ethernet port and ran them through the hole on the right side of the MakerBot in the back on the top. Then connected those leads to the appropriate ports on the extruder board.

- Once the wires were soldered up and extruder assembled I plugged the ethernet jack into the ethernet port and checked ReplicatorG to see if I could get a thermistor reading (yes) and heat the barrel (yes).

As I tinker and modify my MakerBot it seems I’m moving towards a system where I try to make the extruder assembly as modular as possible. I didn’t have this as a conscious thought when I started, but that’s where these modifications have been headed. While it is very convenient to have a totally modular extruder only connected to the robot by four bolts and an ethernet cable, that system is most useful if you are using drastically different print heads (such as a frostruder, Paxtruder, Bowden extruder, etc).

If you’re just swapping between PLA, ABS, or other plastic filament or color variations thereof, you can reuse the vast majority of the extruder assembly – the board, the motor, and the entire acrylic plastruder. If you had a different heater assembly you could just undo the two screws that attach the heater to the extruder, disconnect the thermistor, disconnect the nichrome, and swap in a new set. Although I don’t have a fully assembled second heater section yet, this set up makes a lot of sense to me just for ease of maintenance and repair.

- While I sing Christmas carols with my friends Meryl and Cheryl. [↩]