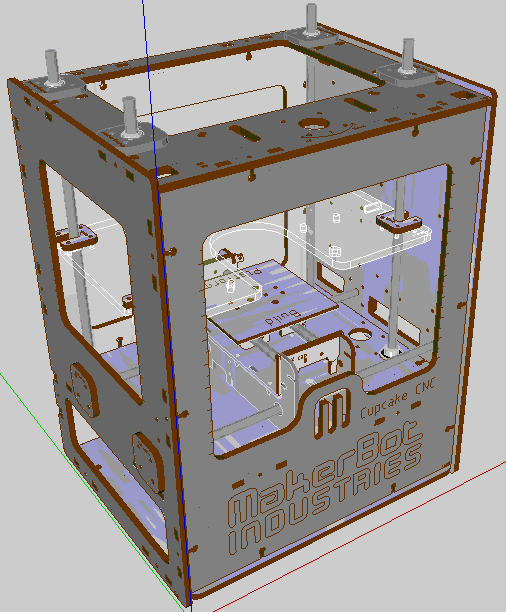

Painted my MakerBot lasercut wood parts (and plastic pulleys!) today. Here’s what I learned:

- Spray paint cans work better when they’re not pointed downwards, so it helps to angle/elevate one part of the painting surface. 1

- Too much ventilation or cross ventilation will let debris fly into the room.

- Position the things to be painted close together, it will help you paint faster and will waste less paint.

- Use primer and buy two cans. Although, had I positioned the pieces more effectively I may not have needed the second can. Then again, I think it probably would have worked better to put even more primer than I did.

- I wiped the edges of some of the smaller parts, but not all of them. The end result is that some paint wiped off as it had adhered to the ash from the lasercutter. I think I like this effect as it made the parts look a little worn, but you may not.

- If you’re painting your MakerBot, don’t forget to consider painting the pulleys!

- Sand down any stray plastic parts off of the printed pulleys before you paint them. I didn’t realize the clearance on the small pulley was so low, and I had to sand the painted finish to get it to fit properly.

- Make sure no parts accidentally shift and overlap before you start painting. It won’t be a big deal, but it’s a little extra unnecessary work to paint it.

- If you’re spraypainting different colors, cover other parts while you paint a new color. A fine mist will be deposited on those other parts. I like the effect, but it may not work for you.

- Keep in mind that if you are using a primer and then a coat of paint some of the parts won’t fit as well (or may fit better!) when you go to assemble the robot. I found it necessary to sand away nearly all of the paint on a few body panel tabs. I also needed to sand away the pain that got on the inside of the round X and Y axis mount holes.

- If you’re painting the “MakerBot Industries” logo on the front a different color than the surrounding body, you probably want to do it at this stage. I didn’t even think about it until I started assembling the body. It won’t be a problem to paint it by hand later, but I could have done this all at once.

- I guess this is why you see graffiti on walls, not floors. [↩]