Dang.

A co-worker just reminded me that Monday is a holiday. If the parts don’t arrive today or tomorrow, I’ll be waiting until Tuesday.

Patience… patience…

Default Series TitleDang.

A co-worker just reminded me that Monday is a holiday. If the parts don’t arrive today or tomorrow, I’ll be waiting until Tuesday.

Patience… patience…

Default Series TitleI don’t think all of my parts are going to arrive in time for me to take a crack at assembling a DrawBot this weekend. Per the USPS:

I think the best I can hope for is getting my motor shield tomorrow. That’s okay, there’s plenty to do in the meantime. I must learn patience.

Default Series TitleI’m not going to actually link to DMCA dot com because I don’t want to send any Google juice their way. 1

This is just so freaking evil I cannot believe I didn’t think of it. 2 DMCA take-down services? Are you kidding me? They’ll charge you $10/month for the ability to send e-mails. The only thing they really have going for them, from what I can see, is a really nice domain name and a snazzy website. Watermarking images and little badges on your site does more to market them than it does to protect anyone.

Edit: Oh, yeah, thanks to Tbuser for the link!

I came across this website as a result of something I was researching for work.

I merely thought the website was bad until I saw a rainbow armadillo shoot stars out of its butt.

Then I realized it was all so much worse. It is perfectly safe-for-work. It may send you into seizures, but it’s safe for work.

I’ve made a few slight modifications to ProfileMaker.

First, after testing it seems that the apparent optimal W/T is approximately 1.67 or so. Using this value for target W/T setting has lead to my cleanest and most sturdy prints. Admittedly, I haven’t done proper science-testing to determine the optimal value – but I do not believe it could be far off. Thus, I’ve removed this setting option and ProfileMaker will calculate the optimal thread width based upon a W/T value of 1.667 and whatever layer thickness you choose.

Secondly, I’ve removed the automated profile creation system. Not many people seemed to be using this and this feature gets quickly outdated a new versions of ReplicatorG are released. While the five critical settings provided by ProfileMaker have been unaffected by recent changes to ReplicatorG’s Skeinforge engine, lots of the other settings have been juggled around. Skeinforge is too much of a moving target for me to try to keep up. Ideally, you’ll find a good set of profile settings you like and will still be interested in using ProfileMaker to adjust the five critical settings.

It is my hope that by making these minor changes everyone will have an easier time using ProfileMaker and get better results.

Please let me know what you think!

As you may know, I’ve got a MakerBot Cupcake named “Bender” and a MakerBot Thing-O-Matic named “Flexo“. There’s really no doubt in my mind I’ll be springing for a Replicator with dual extrusion. 1 Thankfully, I think there’s a way for me to make use of each of my robots, in its own special way. I figure I can keep the Cupcake rocking a Unicorn Pen Plotter, use my Automated Build Platform in my Thing-O-Matic for mass production of smaller parts, and put a Replicator to work printing new, wacky, and/or large designs.

But, why am I talking about giant unicorns?! Sandy Noble, the creator of the Polargraph,2 just posted about how he has created a vector graphics importer for the Polargraph software. This is some pretty amazing stuff. The MakerBot Unicorn has several software toolpaths that take vector graphics to GCode for printing through ReplicatorG. The end result is that a Polargraph rocking a vector graphic importer should be able to draw arbitrary shapes, without the need to draw scribbly bits.

I think it would be particularly awesome to have a DrawBot draw a frame/border and then fill it with a scribbly/pixelated drawing. Or, perhaps, draw the outline of an object and then fill it in with scribbly/pixelated shadings.

Default Series Title

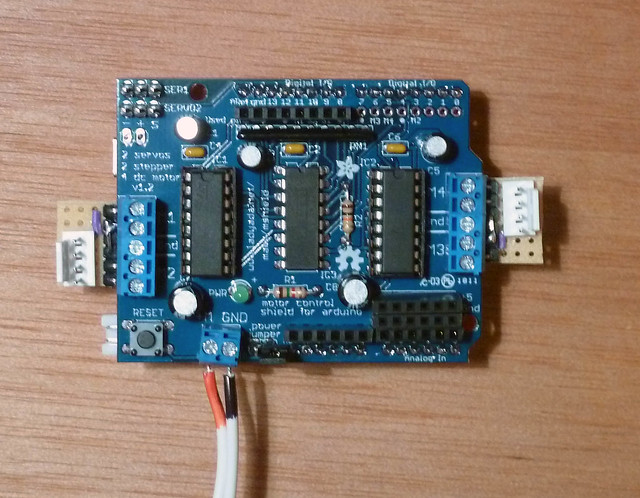

Chatting with Sandy Noble over at the Polargraph website has been extremely helpful. 1 It looks like he’s added three changes to the Adafruit Motor Shield:

What’s next?

If you’re just tuning in, I’m going to be building a DrawBot. Or, in the alternative, I intend to fail as spectacularly as I can.

However, it occurs to me that I need not be constrained by just my ideas of what a drawing robot should draw. Admittedly, several of my anticipated print jobs are going to take a while since my daughter already has a stack of drawings she wants a drawing robot to replicate. Here are the things I’m thinking about drawing:

So, if you had a drawing robot that could create sketches of arbitrary size, what would you draw?

Default Series TitleYesterday I placed an order with Adafruit and MakerBot for all the parts I’ll need to build a DrawBot. The MakerBot order shipped that same day and I just got a confirmation that the Adafruit order has shipped.

According to the USPS priority shipping estimates, it should take 2 days for these packages to get from Brooklyn to the SF Bay Area. I figure it will probably take three. So, hopefully the parts will arrive on or Saturday. I’m really excited about building a DrawBot and my daughter is too. She’s been drawing sketches for me to scan in for when we get the robot operational – so we can blow them up super huge.

Default Series Title