I’m used to seeing 3D printing services advertising in the Google ads on Thingiverse.

Then I was searching for dog barking collars. A few hours later, back to Thingiverse… dog collars?!?!

Cut it out!

Default Series TitleI’m used to seeing 3D printing services advertising in the Google ads on Thingiverse.

Then I was searching for dog barking collars. A few hours later, back to Thingiverse… dog collars?!?!

Cut it out!

Default Series TitleApparently I can’t access Google Groups. Which sucks. I have several different Gmail accounts and I can’t use any of them with Google Groups. As a result, I can only read what’s going on in the Google Groups on my RSS feed – and not respond to anything.

Google, this may not be evil… But it is just plain mean. Cut this out, please, and restore access to Google Groups to Gmail users.

Default Series TitleThese look promising…

http://www.ohyeahcad.com/download/

I’ll try them out and let you know.

As I’ve mentioned before, I do all of my 3D modeling in Sketchup. It’s not open source, but it is free.1

Well, I’ve been monitoring the Capolight Electronics Blog lately – and it’s a good thing too. Besides having some seriously amazing information about the thermal properties of plastic, he’s just posted about some useful importing/exporting plugins for Sketchup. As easy as Sketchup is to use, it’s just not very good at exporting to STL. I haven’t tried these plugins out – but I’m hopeful they will do the job.

If you try them out, please let me know how it goes!

Ricardo Santos managed to create PLA in his home. My Portuguese is pretty rusty. Well, to be exact, non-existent. However, that’s what Google is for! Thanks Ricardo!

I’m a big fan of Google Sketchup. I know it’s not open source, but damn it sure is easy to use. The other day I noticed this blog post about a new Sketchup STL Importer plugin. Earlier I had posted about other useful Sketchup plugins, and this one will probably make my list too. I’ve installed it, but not tried it out yet, so caveat emptor.

MakerBot posted a screenshot of a RepRap Printed Mendel Parts auction that sold for 420 pounds – roughly $630.84. 1 2 Others have been posting RepRap Mendel auctions as well. One just sold for roughly $453, another for about $270, with two more auctions around $450 each with at least 3 more hours to go.

Using Spacexula’s Mendel production files, 24 STL sheets of parts, averaging 2-3 hours a print, we’re talking roughly 60 MakerBot print hours. 3 Assuming I only have the patience to print up one STL sheet a weekday and two sheets on the weekends, starting on a sunny Sunday like today, I could finish in 19 days.

Assuming very little human intervention, $600 for 60 hours of MakerBot operation is a pretty good deal. It’s like having a fussy gnome who eats electricity and plastic living in your home and earning just above minimum wage for you. 4

I’ve always been a PC kinda guy ever since my IBM 286.1 PC’s are inherently more modular and hackable than Macs – I can buy any off the shelf no-name brand part and fix something myself.

That said, Zaggo’s software is making me wish I had a Mac. His Pleasant3D v2.0 software is crazy awesome. I use Google Sketchup to design and a combination of Netfabb and Blender to convert formats. But nothing I have lets me view models in the way Zaggo wrote.

Have you read The Hitchhiker’s Guide To The Galaxy? Of course you have.

You remember that bit where they put Zaphod in the machine designed to drive people insane by showing them the entire universe all at once? Well, that’s how Google Wave feels to me. There’s a LOT of freaking information there. I made the mistake of looking directly at the MakerBot wave. It was like falling into the gaping maw of eternity. I’ll stick to RSS feeds, MakerBot Operators group, and Twitter, thankyouverymuch. 1

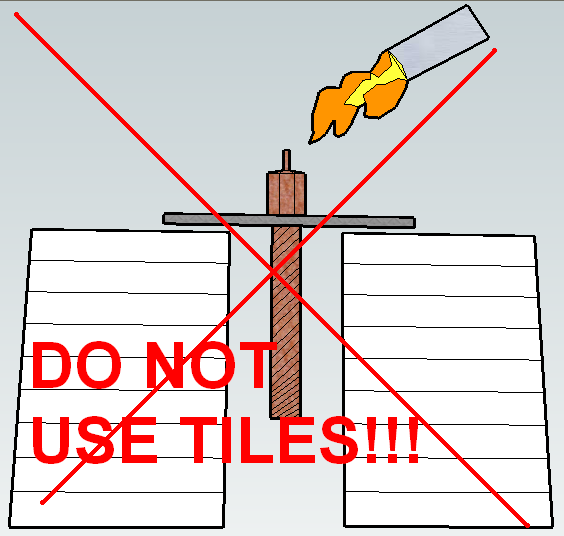

UPDATE: DO NOT USE TILES!!! THEY WILL SHATTER! READ LATEST POST!

The bad news is this is my first clogged extruder. The good news is I have all the spare parts to whip up a new extruder, no problem. That means I can experiment with wild abandon! My backup plan is to slice and dice the PTFE insulator into washers.

Having drilled out most of the plastic clog from the barrel, it’s mostly empty. The PTFE is in pretty good shape with the threads intact, if a little worse for wear. My plan to get the remaining plastic out of the nozzle is to put the nozzle/barrel assembly into the large washer upside down and prop it up on some ceramic tiles.

My hope is that by applying a heat source to the nozzle the plastic will just drip/fall out. The suggestion for using a blow torch to clear out the barrel and nozzle comes from Rick Pollack / MakerGear. Thanks again Rick!

By the way, wicked Google Sketchup skillz, no?