While looking at the Adafruit Drawdio v1.1 I noticed that it runs off of a single AAA battery. That’s certainly small enough to fit into a printed sonic screwdriver!

And, of course, it would make for an actually sonic sonic screwdriver…

While looking at the Adafruit Drawdio v1.1 I noticed that it runs off of a single AAA battery. That’s certainly small enough to fit into a printed sonic screwdriver!

And, of course, it would make for an actually sonic sonic screwdriver…

The title is a complete fabrication. But, that would have been a much cooler way to announce “engineers are already experimenting with ultrasonic waves to move and manipulate small objects.” The sonic screwdriver is (may be) real!

Answer: It’s a lot more convenient than strapping a TARDIS to your wrist.

Ever since seeing the season 5 finale of Doctor Who I’ve wanted my own printed vortex manipulator. I have a feeling Nick Starno’s pocket watch case for the MakerBot Watch would be a good place to start.

Just another random thing in my list of stuff I want to make.

To the right is a first draft print of my latest designs for the sonic screwdriver. It’s next to a USB cable for scale and perspective. There are several things I need to fix:

I’ve posted my sonic screwdriver designs to Thingiverse for people to tinker with and, hopefully, improve. I would sincerely appreciate any help anyone can provide when it comes to designing the upper half of the sonic screwdriver – especially the moving parts.

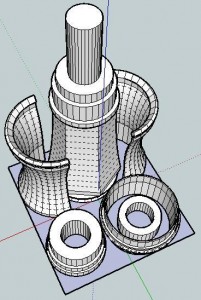

I just redesigned the printable screwdriver in order to make the parts fit together better and be more printable.

It should be easier to see how these parts go together.

Basically, you take the “mid-handle” at the far end of the build sheet, turn it upside right, clamp the two “lower handle” pieces on either side of it, and slide that bottom ring onto the lower handle.

I still need to redesign the upper handle, hollow out the mid-handle, and make sure there’s enough room inside for the GoodFET / electronic sonic screwdriver guts.

Now I’m wondering if it is also possible to make this a piece of MakerBot origami – and make it printable on one build sheet…

This morning I received an e-mail from Bre out of the blue introducing me to Travis Goodspeed. Apparently Travis has been working on building sonic screwdriver guts out of the GoodFET, a universal JTAG programmer, a “sonic screwdriver of hacking.” Travis suggested a GoodFET could be programmed to act as a TV-B-Gone, light show, or any number of other things. Given that his circuit board is about 3″ x 0.85″ x 0.2″1 , there shouldn’t be a problem finding space for it in the sonic screwdriver I’m in the middle of designing. 2

Freaking sweet.

So, here’s my real life sonic screwdriver wishlist:

If I’m printing an object with a 0.5mm thickness, chances are the very first time there’s a slight overhang it will go pear shaped. When the walls are that thin, there’s almost nothing underneath even a very slight 20-30 degree overhang.

Duh.

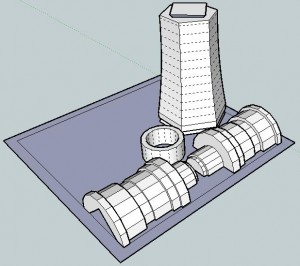

Off to the left is a picture of what the finished sonic screwdriver should look like. Here’s a picture of the parts I’ve designed so far. Assembled properly, these parts should be able to be assembled into the lower half of the sonic screwdriver.

I’ve arranged the parts so that they have a less than 60mm x 60mm footprint on the build platform. I would really like it if the final product could be printed all on one build plate and assembled without tools or additional non-printed pieces.

After my recent design-print fail, I’m going back to the drawing board (slightly)1 wiser. If nothing else, I like to think what I have so far is pretty neat. 2

I’ve been slowly working on the design of a printable (and fully MakerBottable) sonic screwdriver. This model of the sonic screwdriver is built up of a number of concentric cylinders, has several significant overhangs well in excess of 45 degrees, and is larger than the MakerBot’s built capacity. In order to deal with these design problems, I modeled it in sections.

In order to make the overall result something I could just pop/snap/slide together I designed it making some sections which were split vertically and other sections which slide around those sections to keep them together. In order to make the parts quickly printable I designed all the parts at around 0.5mm thickness.

About 40% of the way through the print one of the vertical sections wasn’t coming out properly – probably because it was too thin. The parts were too thin and flexible and ended up tearing between layers and just being too flimsy.

I also noticed something odd – the extrusion was too thin on that side of the model. I can’t be sure why this is happening – but I suspect it’s due to the extruder not getting a good enough grip. Perhaps I need to floss the extruder pulley or install a new extruder idler wheel. However, it doesn’t explain why the extrusion was too thin on just that one side and no other spots.

Suggestions?

I recently bought the Perhaps with a joule thief?)1 Since I know very VERY little about electronics, I’d appreciate some diagrams, descriptions of parts, etc.

My end goal is to install this device into a MakerBot made replica of the 11th Doctor’s Sonic Screwdriver.

If you’re interested in this project or just want to help, I’ll gladly accept any assistance. Let me know if I can help with any printing projects in return.

Thanks!