I recently saw an Instagram post from someone I follow who makes cardboard furniture in India. His story of building cardboard furniture while in college during COVID, building hand sanitizer dispensers out of cardboard, licensing this, and then pivoting to creating a business around making cardboard furniture is pretty cool. One part of the story is how this guy’s designs started getting ripped off by others who saw it was an inexpensive and easy to produce product. Even with patent protections, ideas get ripped off all the time. Anyhow, this IG post was about how he had invented a business card which opens into a phone stand and apparently rejected an offer for the equivalent of $1M to sell his patent.

When they won’t license the design or sell the business card itself, I’m not at all sure why it was patented at all.1 They apparently got 10,000 produced, gave most away, and turning down offers to buy individual cards.

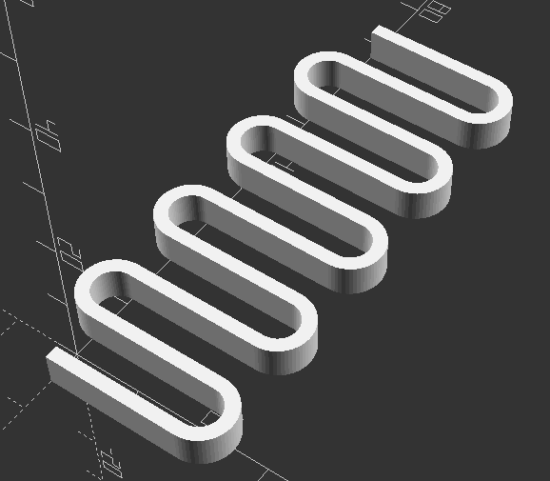

Sometimes when I see something interesting, I think about how it’s constructed and how I could build one using my own resources. Just a quick glimpse at the video reveals pretty much everything one would need to build one. A quick mockup in Inkscape and I had a version printed out on copier paper. It was slightly flimsy, but it works just fine. If I did this again out of cardstock, 300GSM paper, or even thin cardboard, I bet it would even better.

It’s a neat little tool – and I think I will make a few more for personal use. Mine has a rounded front “nub” rather than the angled one in the video. I could see adding an RFID tag/sticker, QR code for info, and other minor functional augments to be more useful to me. I think there’s even a few ways to improve my design a little.

- I tried looking up the patent, but couldn’t find it anywhere [↩]