Axis of Awesome, indeed!

Update: Thanks bpijls!

Axis of Awesome, indeed!

Update: Thanks bpijls!

Actually, Bre just drew a picture for my introduction over at the MakerBot blog. I like the picture mostly because it makes me look WAAAY cooler than I really am. :)

I will continue to blog here1 and offer prototyping and 3D printing services through this website. :)

[pdrpiechart data=”Yes. Ill even donate a dinosaur. Or laser.=27|Only if they promise to make him blog LESS. =4|No freaking way. I hate that guy.=2″]

As you may have heard, I have finally worn down the resolve of MakerBot Industries. They’ve agreed to hire me to blog for them! 1 The negotiations were long and grueling, with tough concessions on both sides.

I promised to stop hanging around outside the BotCave, move back to California, and blog less. In exchange, Bre promised to drop the restraining order. This is really a win-win for everyone!

My recent post about We Alone On Earth’s MakerBot woes (and some solutions!) caught the attention of some people on Twitter, including Tim freaking O’Reilly. As in Make Magazine, Maker Faire Tim O’Reilly.

Guys, if you have any sway with MakerBot Industries, tell them to hire me to blog for them already. :)

[pdrpiechart data=”Yes. Ill even donate a dinosaur. Or laser.=25|Only if they promise to make him blog LESS. =3|No freaking way. I hate that guy.=1″]

96% of people polled want MakerBot to hire me to blog for them. 4% hate me and would rather have a sharp poke in the eye than read another word I’ve written. Oh well, you can’t live your life without controversy.

I’m leaving this poll open until MakerBot hires me, so we should all just get used to it. :)

Ah, Google, you always know how to build an online tool that straddles the line between helpful and creepy. Streetview plus Google Maps? You are truly mana from heaven for stalkers.1

So. It gets kinda cold outside at night. I forgot to bring a sleeping bag, so I’ll just crouch down into a little ball, huddled over this laptop for light and warmth. 2 That Penke truck has moved since the Google van took that picture, so there’s not much of a wind break.

You guys going to let blog for you, or what?

Could I at least get a tour of the BotCave?

Sometimes you just need to turn a problem on it’s head. I see that’s it been over a week since I submitted my job application. 1

So, here’s my counter proposal – I will continue to blog incessantly UNTIL you hire me! Ha – and you thought it was going to be irritating to have me camp out outside, not showering, and stinking up the joint.2 Just wait until I clog up the RSS feed with every bit of nonsense I can dream up. 3

Peter Jansen’s latest post about selective laser sintering (SLS) is nothing short of amazing. Most of his posts on the RepRap Builders blog posts deal with his adventures and research into SLS fabrication – basically directing a laser over a bed of powder to fuse powder in successive layers into a 3D object. Since the object is being created in a bed of powder and any new layer is supported by the powder above it, the powder print media becomes it’s own support material.

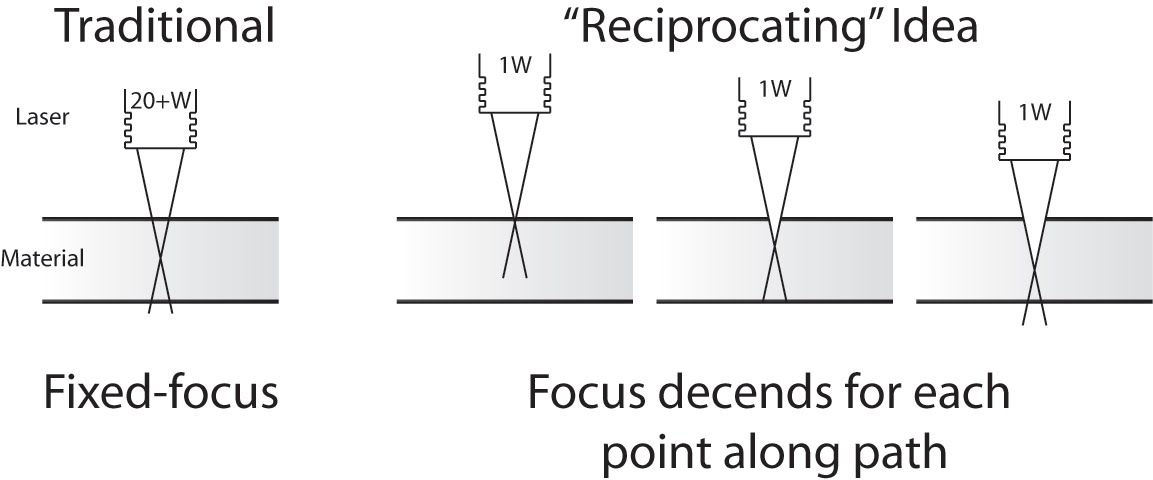

His latest post diverges from his adventures with SLS 3D printing and details his efforts at building a DIY laser cutter. His idea is for a “reciprocating laser” which would change the focal length or the height of the laser above the material being cut. Peter points out that commercial high power laser cutters essentially brute force burn through the entire depth of the material to be cut. They’re so powerful that it doesn’t matter that the laser is out of focus and “cooler” at different depths.

He has demonstrated a proof of concept using much lower power laser to cut material by lowering a much lower power laser as it cuts material. The downside is that the lower power laser requires a much longer time to burn through the material – having to hit the same area several times at different depths to cut all the way through. His proof of concept setup was about the size of a CD/DVD drive – since CD/DVD drives, motors, and housing provided most of his building materials. So far he’s been able to burn through most of two CD case backs – about 2mm together. He’s hoping to push it to cut thicknesses up to 3.0mm to 4.5mm.

The incredibly small size of his setup means that it can only very small pieces of material. However, this gave me two ideas:

TheMitch22 downloaded the 3x2x1 Rubik’s cube v4, printed it, and uploaded a video of it working! The cycle is complete.

100% printable, no hardware or tools required. And it looks amazing in red.