[This is a post I’ve revisited so often that I really have no idea when I began writing it – and couldn’t figure it out without digging deep into the WordPress database. Suffice it to say, I’ve wanted a cardboard cutting CNC for a long time. Originally a collaboration between DARPA and OtherLabs, most of the interesting parts of this project have been removed from Otherlabs’ website and many other resources the victim of linkrot. As a project funded by a federal agency, there’s a slight possibility some semblance of documentation for this machine might still kinda exist somewhere accessible via FOIA requests… The operation isn’t exactly arcane, a reciprocating blade, that can be rotated through 360 degrees, on a rail, and a bed that moves a sheet of cardboard back and forth – like a suped up craft cutter.]

I can’t help it – I love cardboard and I love CNC tools. 1 Cardboard is free or cheap, lightweight, strong, but can look unfinished and is very susceptible to moisture. This makes it ideal for prototypes and temporary projects. However, when a cardboard structure is covered, it can be incredibly strong and durable.

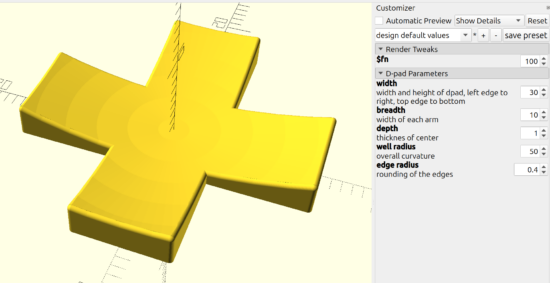

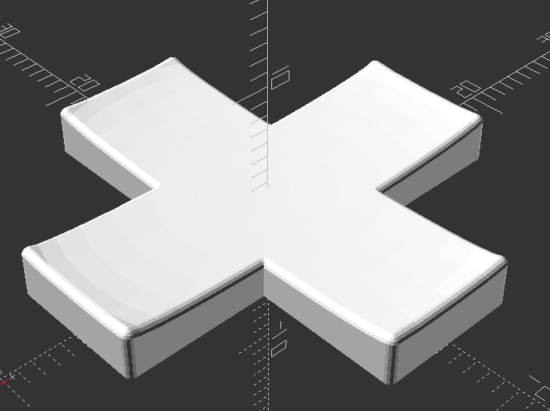

The promise of the Othercutter was a simple CNC machine kit using an off the shelf x-acto blade to cut cardboard or foamcore.

The shortest possible version is that the Othercutter was the brainchild of Otherlabs (now Bantam Tools). What started out as a project to cut cardboard morphed into the Othermill, a small capable desktop CNC mill initially released on Kickstarter. I could never do justice to the Otherlabs and Bantam Tools story – it’s a wild ride and worth a read.

- https://web.archive.org/web/20130209054433/http://blog.mentor.otherlab.com:80/

- https://blog.bantamtools.com/loving-our-own-dog-food

- https://otherlab.com/blog/post/the-othercutter-low-cost-cnc-machine

- https://web.archive.org/web/20130122094442/http://blog.mentor.otherlab.com/the-othercutter-low-cost-cnc-machine/

- https://web.archive.org/web/20130109063100/http://blog.mentor.otherlab.com:80/the-beginning-otherlab-and-the-mentor-project/

- https://web.archive.org/web/20130131051839/http://blog.mentor.otherlab.com:80/architecture-and-the-othercutter/

- https://web.archive.org/web/20130131175353/http://blog.mentor.otherlab.com:80/othercutter-update-speed-and-quality-control-testing/

- https://web.archive.org/web/20130210080545/http://blog.mentor.otherlab.com:80/cardboard-in-the-wild-marty-morales

- http://kimlyis.me/otherlab-otherfab/

- https://sites.google.com/site/3dprinterlist/cnc-cutters/othercutter

- https://ingriddragotta.com/Info

- https://www.youtube.com/user/Otherlab/videos

- https://arstechnica.com/information-technology/2013/05/a-day-at-the-bay-area-maker-faire-the-greatest-show-and-tell-on-earth/

- https://www.mssm.org/uploaded/STEM_Collaborative/2013_Educators’_Camp_Course_Selections_.pdf

- https://web.archive.org/web/20101231104932/https://www.fbo.gov/index?s=opportunity&mode=form&id=0248c338123e8b6f51d4dcf743196464&tab=core&_cview=1

- The Lost Blog Posts

- Plastruder! [Draft 12/25/2009]

- UNTITLED [Draft 12/25/2009]

- Preparing to print [Draft 12/27/2009]

- More prints [Draft 01/04/2010]

- Prototype Pricing [Draft 01/19/2010]

- MakerBot tuning [Draft 01/20/2010]

- Plastic Screw Anchor [Draft 02/02/2010]

- Magic [Draft 02/03/2010]

- How are you printing with PLA? [Draft 02/16/2010]

- Rebuilding my extruder [Draft 02/16/2010]

- MY robot [Draft 02/18/2010]

- more things i learned [Draft 02/20/2010]

- First commissioned piece! [Draft 02/22/2010]

- MakerBot: Toy or Tool? [02/25/2010]

- Idea for Skeinforge settings… [Draft 03/27/2010]

- RepRap and MakerBot alternatives [Draft 04/05/2010]

- RepRap Parts for Sale [Draft 04/07/2010]

- Where is the Othercutter? [Draft 06/08/2015]

- Gotta collect them all. [↩]