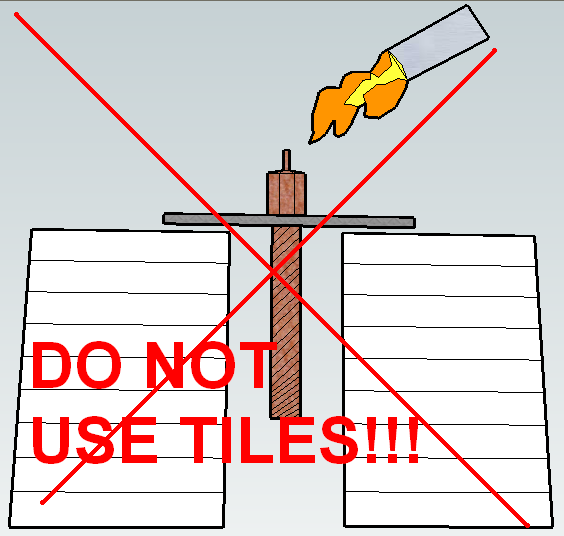

UPDATE: DO NOT USE TILES!!! THEY WILL SHATTER! READ LATEST POST!

The bad news is this is my first clogged extruder. The good news is I have all the spare parts to whip up a new extruder, no problem. That means I can experiment with wild abandon! My backup plan is to slice and dice the PTFE insulator into washers.

Having drilled out most of the plastic clog from the barrel, it’s mostly empty. The PTFE is in pretty good shape with the threads intact, if a little worse for wear. My plan to get the remaining plastic out of the nozzle is to put the nozzle/barrel assembly into the large washer upside down and prop it up on some ceramic tiles.

My hope is that by applying a heat source to the nozzle the plastic will just drip/fall out. The suggestion for using a blow torch to clear out the barrel and nozzle comes from Rick Pollack / MakerGear. Thanks again Rick!

By the way, wicked Google Sketchup skillz, no?

Something really really useful as a heat source is a soldering iron. Just put some solder on the tip of the iron and touch that solder to the nozzle. Hold it there for a few minutes and it should either ooze out or it gets to glass transition phase and you can pull it out. This is assuming the PLA isn’t burnt. Which you said it was. So in that case you should use a blowtorch and respirator… But its an idea for future clogs.

I would think an electric heat gun would get hot enough to melt the clog, while still being much cooler than an open flame. Maybe a little safer and easy to control. We use an electric heat gun to remove soldered SMT components, so I think they would be hot enough.

I’m not sure melting would have done the trick – I actually ended up just burning the contents out entirely. I might have been possible for me to crank the heat on the extruder to try to melt it out. But, I suspect the plastic plugging the extruder might have undergone some kind of chemical change – possibly even getting charred inside the barrel. Either way, burning/vaporizing the plastic out totally worked – and if I run into this problem again I’m totally bringing out the torch.

That said – if you end up with a clogged extruder, please try the electric heat gun and let me know!

Heat gun (hot air rework gun from a soldering station) works to get the plastic out – as long as you have something to push through the .4mm tip. I couldn’t find a needle small enough. Leads off of electrical components (like LEDs or resistors) are too big at .7 or larger. My .4 mm tip has two pieces, the brass piece with the .4mm opening and the larger threaded piece with a much larger (3.0ish mm) opening. For the larger opening I was able to heat it up and push the glob of ABS out with a hex key. But for the small tip I’m stumped without something small enough to poke through.

Going to try my map gas torch in the morning.