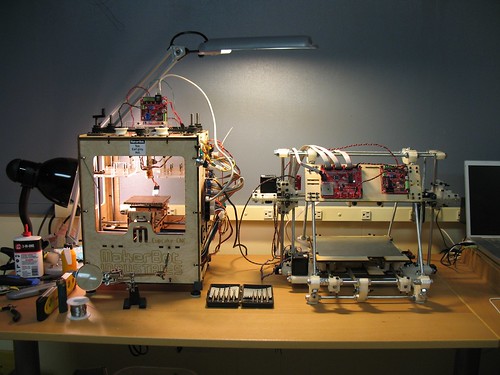

[Holy cow. Can you imagine a time when a person could singlehandedly have made a comprehensive list of all open source 3D printers in an afternoon?]

Here’s a list of all of the RepRap, RepStrap, and MakerBot open source 3d plastic FDM 3d printers I can find. When possible I’ve tried to link to the official site, helpful derivative sites, instructions, and parts. I’ve also included some notes.

- RepRap – The ultimate in DIY personal fabrication technology. Source everything yourself and put it together!

- Mendel –

- parts on ebay

- bearings – http://www.vxb.com/page/bearings/PROD/kit9060

- Mendel –

- Darwin –

- Ponoko Darwin Acrylic lasercut parts – http://www.ponoko.com/showroom/reprap/free-acrylic-reprap-v1-1–2083

- Mini-Mendel

- Isaac Mendel http://isaac-mendel.blogspot.com/

- Fab@Home

- MakerBot –

- McWire – http://reprap.org/wiki/McWire_Cartesian_Bot_1_2#This_project_is_no_longer_actively_developed.___For_newer_mcwire_info.2C_please_see_http:.2F.2Fobjects.reprap.org.2Fwiki.2FDevelopment:McWire

- ShaperCube –

- http://wiki.shapercube.com/wagn/Shapercube_Assembly

- Profound Devices –

- http://www.profounddevices.com/

- RepMan –

- http://www.bitsfrombytes.com/index.php?page=shop.product_details&product_id=168&category_id=5&flypage=flypage-ask.tpl&option=com_virtuemart&Itemid=100005

- Tommilese –

- The Lost Blog Posts

- Plastruder! [Draft 12/25/2009]

- UNTITLED [Draft 12/25/2009]

- Preparing to print [Draft 12/27/2009]

- More prints [Draft 01/04/2010]

- Prototype Pricing [Draft 01/19/2010]

- MakerBot tuning [Draft 01/20/2010]

- Plastic Screw Anchor [Draft 02/02/2010]

- Magic [Draft 02/03/2010]

- How are you printing with PLA? [Draft 02/16/2010]

- Rebuilding my extruder [Draft 02/16/2010]

- MY robot [Draft 02/18/2010]

- more things i learned [Draft 02/20/2010]

- First commissioned piece! [Draft 02/22/2010]

- MakerBot: Toy or Tool? [02/25/2010]

- Idea for Skeinforge settings… [Draft 03/27/2010]

- RepRap and MakerBot alternatives [Draft 04/05/2010]

- RepRap Parts for Sale [Draft 04/07/2010]

- Where is the Othercutter? [Draft 06/08/2015]