If you are going to travel to the future, it is always a good idea to visit a ‘bot convention.

I’m tired and happy and have so so so much to blog about…

Category: MakerBot

All things MakerBot! MakerBots, RepRap, and robots!

Planning for time travel isn’t as easy as you might think

It is my intention to travel in time in about three days. My plans are as follows:

On Thursday December 9, 2010 I plan to travel back in time 3 hours along my personal timeline.

On Sunday December 12, 2010 I shall travel forwards again by 3 hours.

Upon meeting people I shall declare unto them, “Lo! I am from the future! And it is a glimmering shiny place! I cannot wait for you to see it!”

Ultimachine plastic

MakerBlock Testimonial from Les H

A few weeks ago I was contacted by Les H. about helping his company prototype a design.

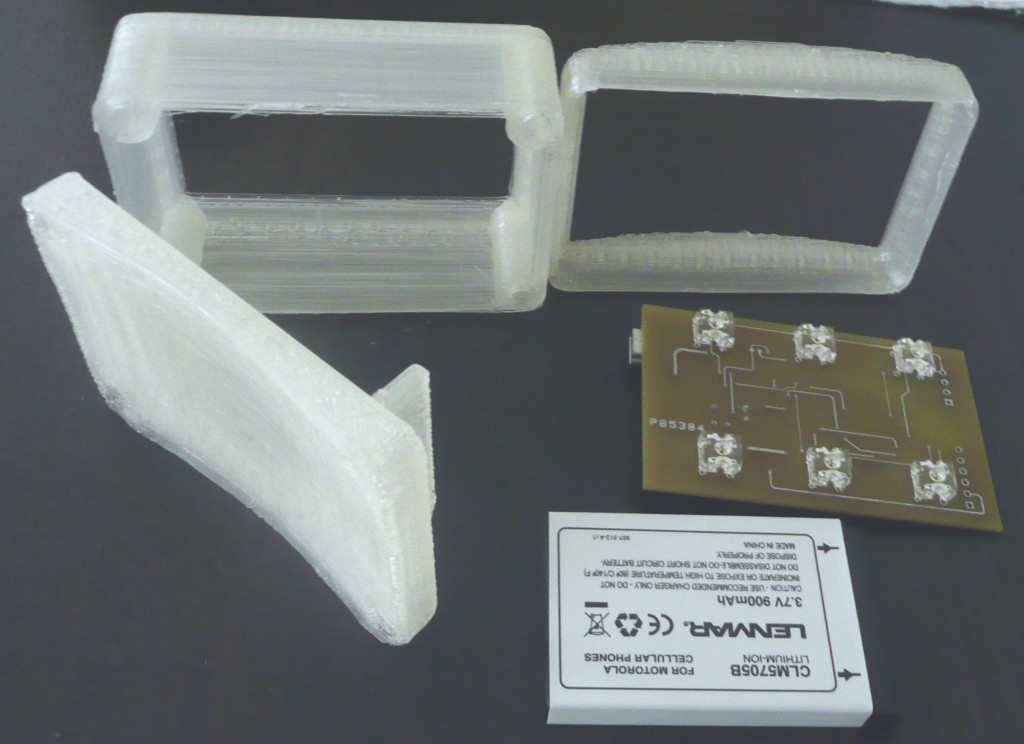

Jay is very knowledgeable about his machine’s capabilities and any pitfalls. His advice enabled us to get a pretty good first prototype out quickly, which showed some deficiencies in our design, and recommended changes to make the design more robust and enable his machine to print it easily. We are about to make the second run. Jay’s suggestions about wall thickness, design elements and dimensional requirements have made us pretty sure that this will be the one we use (unless I make a mistake on layout or measurements). What he printed for us was exactly what we specified, and he worked with us to accomplish a moderately difficult design shape. I am not a mechanical designer, so his assistance filled many gaps in my knowledge. Check out the photos. It all fit together right the very first time.

My advice, go with Makerblock for your prototyping needs.

Regards,

Les H

They had originally expected to go through several design iterations before getting a usable prototype. By exchanging a few e-mails and discussing their designs we were able to eliminate those intermediate print jobs.

Thanks Les!

Has anyone ever finished a printed chess set?

I’ve seen multiple chess pieces on Thingiverse, but I’ve never seen a full black and white (or any two-toned, for that matter) printed chess set. Do you know if anyone has ever done this already?

I’ve got all 16 pieces in black ABS, but have been struggling with PLA. Then, as I am wont to do, I’ve gotten distracted with this or that project. I’m determined to print out all of the pieces in time for Botacon. I’d really like to play a fellow MakerBot/RepRap operator with a totally printed set. I’m less concerned the type of board we’re playing on – it could be a piece of fabric for all I care.

Default Series TitleBotacon talks!

So, hey, there’s going to be this whole Botacon thing. Basically it’s about awesome robots and people talking about robots and people showing off their robots. 1 What would you like to see and hear at Botacon? Help us make it awesome by taking a super short survey, sending an e-mail, or leaving a comment on the MakerBot blog. Also, you can even submit your own ideas for a talk!

At the risk of sounding narcissist, would you want to hear from me? 2 If so, about what?

Chess set: 1/4 complete

I’ve been working on printing a chess set today.

Yesterday I was troubleshooting my automated build platform. I could use it reasonably well as a heated build platform, but the automated part was not working so well. The main issues I was having were the thermistor only registered 255, the automated build platform only ran backwards1 , and the extrusion would not stick to the conveyor belt.

Believe me, some of these issues were incredibly dumb. No worries, I’ll fill you in on the extent of my ignorance soon enough. It’s not like I’ve got a finite supply, right?

I took out the automated build platform conveyor belt – and lost one of the little plastic bushings in the process. I’m pretty sure I can rig a serviceable facsimile, but my printer has been down so much lately that I just want to actually PRINT things. I’ll work on fixing up the automated build platform and troubleshooting it later.

So far I have, in black ABS, 8x pawns, 2x knights, 2x rooks, and am in the process of printing a bishop right now. (I know that’s more than 1/4 of the way done – but I was 1/4 of the way when I started this post).

Default Series Title- WTF? [↩]

Working on my automated build platform

I had some technical trouble with my automated build platform today. (Yesterday? Last night? It all blurs. :) )

I’ve fixed some problems and found others.

Right now I think there may be a slight kink in my filament spindle box. The extruder motor kept running but no plastic came out in one build job. I can successfully print using the ABP as a heated build platform – but it is only really successful with single print tasks. More than that and it screws up the raft.

I’m tempted to lightly sand the automated build platform belt to see if that helps. If not, a friend suggested using blue painter’s tape on the platform. I’ll try the tape first tomorrow.

I did it!

I desoldered the burned H bridge on my extruder board and soldered in a new one!!! I’m so freaking happy!

I’ll be posting the details soon…

Anyone in the Bay Area with a burned out extruder board?

It will be mine. Oh yes, it WILL be mine…

MakerBot just announced their brand spanking new 3D printer – the Thing-O-Matic! As far as I can tell, the highlights are as follows:

- Automated Build Platform – version 2.0??? Guys, I just built my version 1.0 a few DAYS ago! Did you design a time machine to let you import new developments from the future?

- MK5 Plastruder – I’ve got a MK5 and I’m very very happy with it.

- Internal electronics like Charles Pax’ Muffin CNC. The wires sticking out all over on my ‘bot make it look extra DIY. Having all the electronics and wires inside certainly make the Thing-O-Matic appear more like a real honest-to-goodness appliance.

- Generation 4 electronics. I don’t know what in all this means – except that I can plug a standard USB cable into it rather than the funky cable I currently have and it will allow for some kind of automated printing. The Cupcake requires a fair amount of attention when you’re setting it to build something – getting the print head to the exact right height is something you just get used to. For all I know, there are other improvements with the Gen 4 boards – but I’m waiting to hear just like you guys. :)

- Higher resolution. I can’t wait for more details!!! From the announcement post, it appears that Z axis will move much faster – fast enough that the blobs that can occur between layers could be a thing of the past. These have never been a huge problem and I’ve gotten used to a little post-production finishing on my parts – but it would be great to not have to do nearly as much.

I’m wondering how the Thing-o-matic homes in on the correct start position? Does it do this with opto-endstops?

What do you want to know about the Thing-o-matic?