The other day I pointed out the crazy build quality achieved on a RepMan. This is all good and well for RepMan owners – but can your MakerBot get this kind of resolution and build quality?

In a word, YES. A MakerBot is capable of moving the Z axis in increments as small as 0.003125 millimeters. Obviously, the downside is that going from a resolution of 0.6mm thick layers to 0.2mm means your MakerBot will take three times as long to complete the print task.

But, you didn’t buy a MakerBot because you wanted to make things fast, did you? You wanted a MakerBot because it was the only way to make the crazy things you’ve been dreaming about.

Then again, there’s no reason you couldn’t devise several different levels of Skeinforge settings – for varying levels of print resolution, speed, and durability. With that in mind, you could rip out a quick low resolution draft of a part with a low resolution, check to make sure it is suitable for your purposes, and then take your good sweet time in printing a super high quality version.

Easy for me to say, eh? I’m still dialing in my Skeinforge settings for maximum resolution – so having several different resolutions in my back pocket is a pipe dream yet.

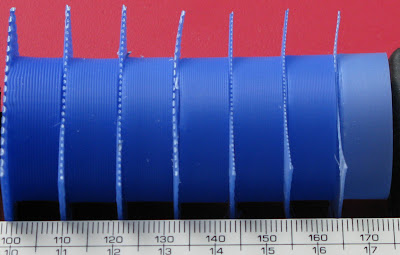

What I’d like to do is print off and install a set of the Z-Wobble reducers created by MakiYoshida. The only question I have about this (truly fantastic) part is whether you lose a little bit of Z resolution – or cause one or more of the Z axes to slowly misalign. If the part holding the nut captive isn’t attached to the Z stage in some way (in the case of this Wobble reducer, via a plastic peg sitting inside the slot in the Z axis) you could end up with one or more Z stage axes slowly becoming misaligned throughout the build.

But, this is all belly button gazing (hence, the lint reference above). I should print a “before” part, crank out four of these Z Wobblers, slap them in, and see how it compares! If I can reduce Z wobble without going through the hassle, delay, and expense of getting perfectly straight Z axis threaded rods by simply printing off a few plastic bits… I’m ALL over that.

I remember reading about the Gingery Lathe a long time ago. Not knowing much about metalworking or lathes, I was impressed with the description as well as the claim that as you built a lathe from scrap and following Gingery’s directions, you could use the portions of the lathe already built to help finish it.

This got me thinking… Wouldn’t it be pretty cool to have a MakerBot kit that came with all the parts to get it printing low quality/resolution parts – and then slowly print up all the bits you need to create a higher resolution, more reliable machine? Then I began to wonder… what if this is what I had already? I’ve got the MakerBot – add in the X/Y tensioners, Z axis cranks, Z axis wobble arresters, replace clunky lasercut layered parts with single assembly printed plastic parts.

We’ve seen a MakerBot replicate, but how far can you push the machine with just printed upgrades?