Of all the bits to get working on my MakerBot, the Plastruder MK4 was the most challenging. There were so many ways for some critical component of the Plastruder to go wrong. You could:

- Cut the wrong length or resistance of nichrome wire

- A small patch of nichrome fiberglass insulation is scratched off, creating a short

- The nichrome is not wound close enough to the barrel, requiring extra power to heat

- There’s too much space between the barrel and nozzle, creating a gap where plastic and build up and cause a blockage

- Heat can travel up the barrel and plastic can ooze up the threads

- Heat can travel up the barrel, plastic can pool and then cool causing a blockage, bulge the PTFE

- The thermistor can burn out or short out

- Heat can cause the thermistor or nichrome to become unsoldered or lose connectivity

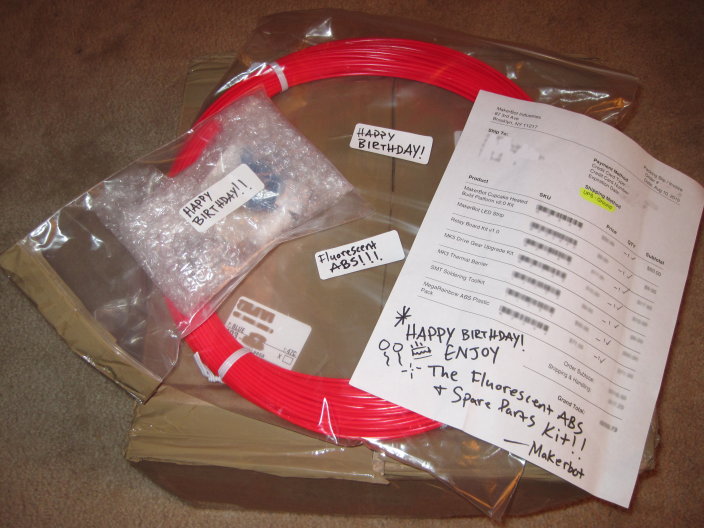

From the description of the new Plastruder MK5, it sounds like the improved designs solve all of the above potential problems!

Update: Beak90 offered several other possibilities!

- one could not heat it up enough and strip the PTFE threads.

- one could heat it too much and cause the PTFE threads to fail.

- one could put the thermistor in the wrong place and have it read the wrong temp.

- one could wind the nichrome in 2 layers and have it not heat enough.

- one could tighten the nut on the barrel too much and cause extra stress on the PTFE causing it too fail.

- one could forget to say the required magical incantations before firing up the plastruder causing everything to fail.

And, one more I just thought of:

- Fail to play Daft Punk