Having printed up and played with a big pile of Beco Blocks, I have come to the conclusion they are only about half of what I was looking for. Mind, they are probably the more difficult half.

The articulated joints you get with Beco Blocks are absolutely fantastic. The connect well, disconnect well, are very moveable, and reasonably poseable. Unfortunately, it is very difficult to build a rigid structure with them. After you play with the parts a bit they become even more mobile and less poseable – but this is to be expected.

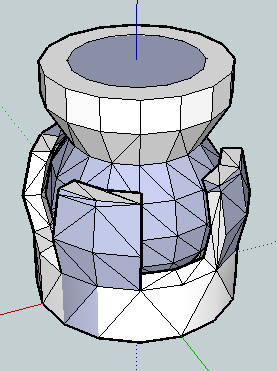

So, how would one go about building a system of rigidly connectable blocks? There’s the Construx way – of side/slide/snapping parts together. Then, there’s the snap/push the parts together Lego way.

Something to think about.