Welcome to Radio Shack!

This post could also be entitled, “Customer Service Fail Day.”

TLDR: If you’re looking to build something, don’t even bother going to Radio Shack or Fry’s Electronics. Even in the SF Bay Area they won’t carry what you need and if you leave feeling disgusted with their customer service, you’ve gotten off lightly. Buy your parts online from someplace awesome like Adafruit or Sparkfun or someplace else that truly cares about what they do.

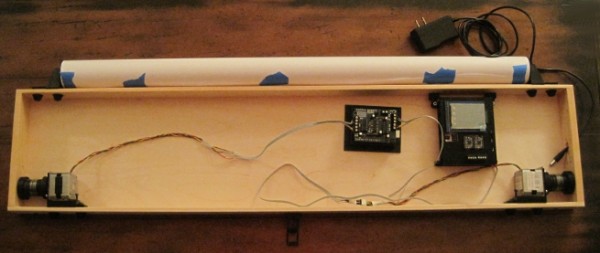

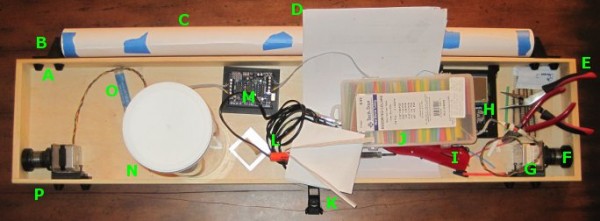

TLRA: Today I went looking for the last few parts I need to properly finish up my drawing robot. If I was able to locate these parts, my ‘bot would be totally ready to place on a wall and start drawing. Even at the risk of overpaying for a minor part or two or spending way too much time trying to locate a mostly inconsequential part, I wanted to try to finish everything this weekend.

I really should not have bothered. I should have just stayed home in my jammies, surfed the net for the parts I needed, and then waited a few days for them to arrive. If I sound disappointed, it’s probably just because I am. I went looking for some fairly basic parts:

- Eight (8) M3x8 bolts

- Multicolored ribbon cable with at least 4 conductors

- Male and female connectors

I would have been perfectly happy to substitute nearly any of these items for something even remotely similar. I would have settled for single color ribbon cable, bolts anywhere from M3x6 – M3x10, and really any kind of male and female connectors that would work. However, all of this is besides the point.

The first stop was a national chain hardware store. I honestly wasn’t sure I wanted to visit this store again, but I had a $5 coupon and I was pretty sure I would find the metric bolts I needed. On a recent trip to the local hardware store I rooted around their nut/bolt area only to discover that someone or someones had mixed many of the M3 and M4 bolts. It was such a mess that I didn’t want to try them again. I paid a lot more for the eight bolts than I was expecting to, but at least I found the exact number of the exact bolts I needed with no additional hassle. While I was there I also picked up an inexpensive 15′ white extension cord so that my ‘bot could have an extension cord of it’s very own.

The next stop was the local Radio Shack. I haven’t been to a Radio Shack in a really long time – mostly because I’ve had such unsatisfactory experiences there. However, given Radio Shack’s long history of being THE place for Makers to find parts and supplies and their apparent return to their Maker-roots, I was willing to give them another shot. The local Radio Shack is in the middle of a run down strip mall nestled between a Chinese take-out place and something else I don’t recall. I honestly thought the Radio Shack was closed until I got right up to it. As I walked up I held the door open for an older Asian lady. She walked in ahead of me and told the clerk, who was on his cell phone, that she needed to borrow $10. Assuming that these two people knew each other, I just went ahead and looked for where they keep components. Electronic toys up front, phones on the left, tablets and computers on the right, and towards the back under the television blaring some sports game I figured I might find some electronics components. The “aisle” was probably only about six feet long and about four feet high. Towards the entrance there were a few Arduinos and books on the left, speaker wire on the right, and at the back of the aisle on the left was a set of pull out drawers with various bits and bobs that could be used in electronics projects. Except none of it was what I needed. The other employee, a woman, walked over and asked if she could help me. I explained that I needed some ribbon cable and connectors, then I had to explain what they were. Once I had done so she pointed to some colored single-conductor wire. I tried to explain that a ribbon cable had more than one wire in it – and this time she pointed to the same single-conductor wire and then another set of single-color wire of a different color. Seeing that this was completely futile, I asked about connectors. Quite helpfully, she pulled open the drawer marked, “Connectors” and told me that any of them would work. I explained that I needed something I could solder to the wire I was hoping to buy and then be snapped together or pulled apart as needed. She picked up a random baggie of plastic and metal and told me that all the parts were in there. I told her I needed male and female parts. “Yeah, it’s in there.” Since she was pointing to a wire crimp with an eye terminal, I knew that either she had no clue what she was talking about or that she just didn’t give a damn about what she was saying. I honestly cannot understand how that store can justify having two employees at that location at any time, let alone at 2pm on a Sunday afternoon when I was literally the only potential customer around. There cannot possibly be enough consumers of radio controlled cars to keep the lights on in that store. The selection of parts was just abysmal and the service could only have been worse if the staff cared enough to actively insult me. After rooting around in the component drawers for a little, I gave up and walked out. Two employees and neither of them said a single thing as the only potential customer they might see that day walked out the door.

My third stop was to Fry’s Electronics. The parking lot was packed and the store was busy. What I love about this place is the parking lot is ALWAYS packed and the store is ALWAYS busy. It doesn’t matter if I come by first thing in the morning, or in the middle of a weekday, or a Sunday afternoon – it’s nearly impossible to find a parking spot and there are tons of people in there. While their staff aren’t always super helpful, I’ve found that about every other employee is actually somewhat knowledgeable about their wares. I walked into the store, past the bargain bin items, took a left at toys, and walked on towards PC components. Since ribbon cables and connectors are the sorts of things one would find inside a PC, I figured this would be the place to start. At the podium stood three young men dressed in black pants and white shirts wearing name tags – I assumed they worked there. The three of them were talking to one another and continued to do so as I stood in front of them. Finally, I said, “Hi!”. The three of them looked at each other and one of them, after several seconds what seemed like a nonverbal game of chicken to see who could go the longest without acknowledging the customer, one of them finally asked how he could help. I explained I needed ribbon cables and connectors. He showed me to wire and speaker wire. I explained that ribbon cable involves having multiple strands of conductors attached together to form a sort of “ribbon” of wires that ran together. He must have been spying on me at Radio Shack since he ran through the process of pointing to colored wire, then showing me two different colors of wire. After holding up a thick piece of electrical cord involving two-conductor wires each separately shielded, but attached by plastic, and miming what it would look like with many more wires along side it – but not as thick, he seemed to understand what I was talking about and took me towards some computer ribbon cables and connectors. After an afternoon of searching I felt that I had finally arrived at the right spot. I asked about male and female connectors or perhaps some male and female headers or anything of the sort he looked back over his shoulder towards his comrades and gestured vaguely towards the wall of parts in front of me and suggested I could find what I needed there. I asked him a few more questions while I rooted around for something that could work. Finally he asked if there was anything else I needed. I could tell there was no way this guy was going to help me any further so I thanked him and let him go. I ended up buying some male headers and a set of 4 pin connectors.

Here’s what I’ve learned from my experiences today:

- Radio Shack is a big fat waste of time. I wouldn’t even buy a remote controlled toy car there.

- Fry’s Electronics is a big fat waste of time – unless I am in need of an off-the-shelf computer component and require zero assistance.

- Buying parts online for a better price is absolutely, positively, worth the wait.