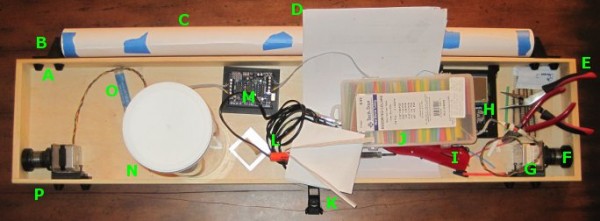

Unfortunately, it will be a few more days yet before I can completely finish the drawing robot. I still need to order some rainbow ribbon cable and connects, wire up the motors, and then actually draw something with the brand spanking new PolargraphSD brain. For now, please just ignore the mess of wires and the superfluous Arduino + Adafruit motor shield in the middle. The blue tape on the paper roll is just there to keep it from unfurling.

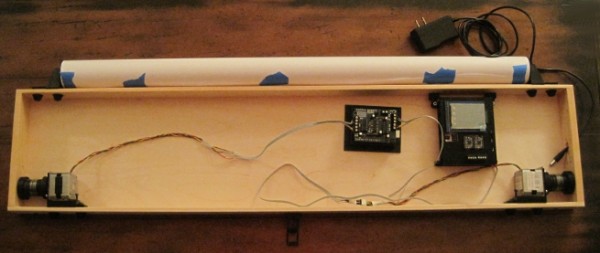

As you can see, the project box looks so much better without all the clutter inside. Once I’ve gotten everything all set up and tested, I plan to add some internal wire guides to keep the wires in check. That should help the whole project look a lot more clean and pleasing.

I’m fighting my perfectionist1 to keep printing and reprinting parts. I had the idea to have dualstrusion printed spools. I know from experience that rotating single color spools don’t look all that much different that from non-rotating single color spools. A spool with a dualstrusion pattern embedded in it would provide some kind of interesting visual confirmation that the robot was operational. Then again, I do like having a very monochrome project – unpainted, unvarnished wood, black ABS plastic, and black oxide bolts.2

You can see above that I’ve already drilled a rough hole into the right side of the box to route the power cable through. There’s just enough clearance in that hole to allow a USB-B cable to go through as well.

I’ve tried to use a very modular system that allows me to loosen and tighten parts in place with a single bolt. While making minor adjustments here and there, this system has been amazingly useful.

I’ve taken several more pictures of the various plastic parts and how they fit together. I’ll post about these shortly.3

Default Series Title- Yes, I do have some perfectionist tendencies… [↩]

- Except the shiny M3x8 bolts used to mount the motors. I wish they didn’t bother me as much as they do. [↩]

- Well, to be perfectly accurate, I’ll post about these plastic parts soon. If you’re a regular reader of the blog, you’ll note that few of the posts could be legitimately described “shortly.” [↩]