… is still progress.

I designed a planetary gear assembly, more to see whether parts this small would even turn out than to actually make a working component. The gears are about 3 mm thick, but half of that is the larger part. I forgot that you can’t have a two-level gear mesh against another identical gear, so these didn’t move at all.

I reprinted the parts, this time increasing the center hole size and also removing the teeth off the larger side. It kinda works, but it’s very finnicky. This might be a side effect of these gears being very thin and the teeth very small. I think it’s probably worth sacrificing gear ratio in favor of larger, more consistent teeth.

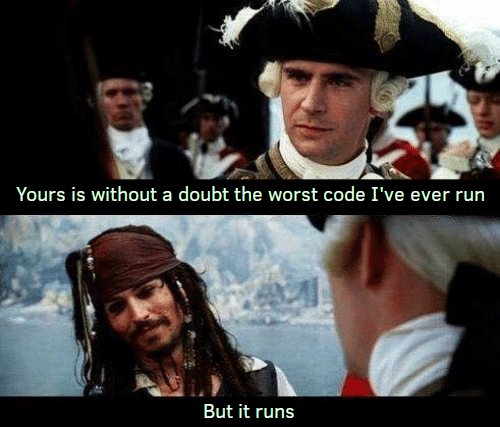

The OpenSCAD code is a mess, lots of vestigial code remains, lots of non-working parts are commented out, and it all just needs more comments in general. I hate looking at it. But, as one of my favorite memes goes…