A broken measuring tape reel that won’t retract isn’t any more useful than a measuring tape without a reel. Thus, there was no harm in cracking thing open to see if I could repair it. Inside I discovered some parts were broken/missing and some parts were lost in the process of delicately opening the case. 1

The modeling of these replacement parts was a very different task from prior replacement parts. As some of the original parts were either missing or too damaged to examine, I had to design replacements from the working/intact parts I did have. The best part is that this involved far more creativity than my prior printed replacement parts such as the window latch and toy fire truck swivel.

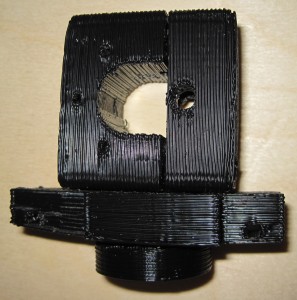

My fix started off by modeling a new interior metal coil spring holder. However, the axle from the original plastic part had become so damaged that it was no longer usable. I had to redesign the exterior piece as well. Unfortunately, the printed exterior piece had its own spindle which promptly popped right off. This lead me to use the two bolts/nuts as the axle. This provides more friction than is ideal – but the entire assembly still works.

I know exactly how I would redesign this with a few additional parts. If I had a single skate bearing and some longer bolts, I’d build a far more robust version. As if I needed an excuse to go out and pick up a pile of skate bearings and an assortment of metric bolts/nuts. :) Alternatively, I can conceive of a version without a bearing that has a foldable crank similar to the foldable Z axis crank.

- Read: jamming a screwdriver into the case and prying apart [↩]