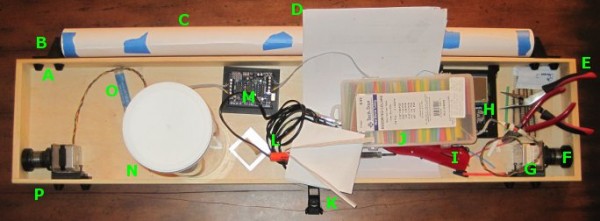

Above is a picture of my drawing robot, still a work in progress. The great thing about this particular project box is that it also doubles as a work area. It’s a good place to cut and strip wires, solder, assemble parts, and it’s totally portable. The box is 3′ long, 8″ high, 2″ inches deep.

- A. Printed Bolt Covers. An M3 nut goes into the recess and the end of the bolt is covered by the printed part. One of these goes over every one of the protruding bolts in the project box.

- B. Printed Paper Roll Mounts, on a Slide. These are actually three separate printed parts. Since the paper roll came without a cardboard tube, I put a wooden dowel down the center, with printed plastic caps on either side to hold the paper in place. There are two printed holders which the wooden dowel slot into. Each of the printed dowel holders slide left and right on a track and have a bolt that can be tightened to keep it from moving.

- C. Paper Roll. After looking in a few craft stores I finally found a big long roll of paper at Staples of all places. I think it was marketed as paper you would use to cover a table. It’s thin paper, but there’s a lot of it and it was really cheap. With no internal cardboard tube, I had to design endcaps to keep it from wobbling all around.

- D. Maker Faire Application. I’m hoping to display this robot at Maker Faire Bay Area 2013. Since the call for Makers hasn’t gone out yet I just downloaded the Maker Faire New York 2012 application and filled it out. Now when the call for Makers comes, I’ll be ready.

- E. Wire Cutters and Pliers. These are just necessary tools. When I need something to hold tiny parts I wrap a rubber band around the pliers and they’re a tiny vise.

- F. Printed Spools. Two printed plastic parts plus three nuts and bolts. Definitely overengineered, but they don’t have the weaknesses of a single print spool.

- G. Motor Bolted to Motor Mount, on a Slide. The motors are bolted to a plastic mount with a groove. The motor mount is then slotted onto the slide which is itself bolted to the actual project box.

- H. PolargraphSD in a Printed Case. I designed and printed the case. The way it is mounted to the project box, it is slightly offset from the box, which gives the circuit boards extra ventilation.

- I. Stick Lighter. I used this stick lighter to heat the heat shrink.

- J. Heat Shrink. Lots of heat shrink in varying colors and diameters.

- K. Printed Gondola. This is John Abella’s gondola.

- L. Soldering Iron. A cheap soldering iron.

- M. Adafruit Motor Shield on an Arduino Uno, in a Printed Holder. Well, that about says it all. I would point out that the printed holder is pretty terrible – it’s just a little too small. The only reason I put the Arduino and shield in the box was so that I could hook up the motors and make sure everything was still in operating condition.

- N. Big Container of Zip Ties. Zip ties are useful.

- O. Solder. For soldering.

- P. Monofilament Guide. You can’t see it, but there’s a little plastic tube that fits into a hole drilled through the wood project box. It’s much smoother than wood and works great.

I’ve taken a lot of detailed pictures of the various parts and how they go together, so that comes next.

Default Series Title

One thought on “DrawBot – A Tour!”

Comments are closed.