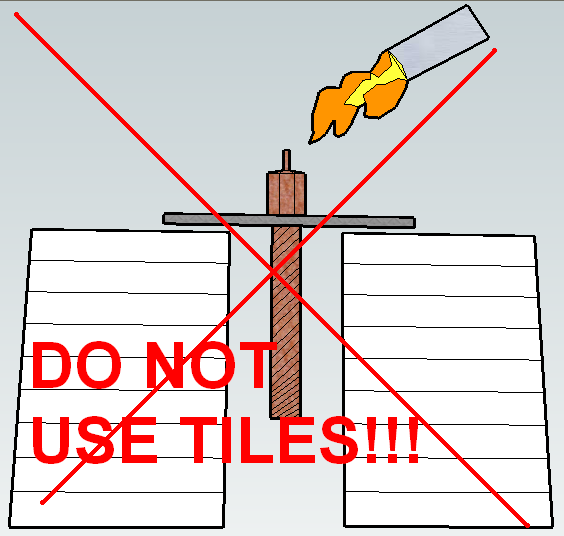

UPDATE: DO NOT USE TILES!!! THEY WILL SHATTER! READ LATEST POST!

The bad news is this is my first clogged extruder. The good news is I have all the spare parts to whip up a new extruder, no problem. That means I can experiment with wild abandon! My backup plan is to slice and dice the PTFE insulator into washers.

Having drilled out most of the plastic clog from the barrel, it’s mostly empty. The PTFE is in pretty good shape with the threads intact, if a little worse for wear. My plan to get the remaining plastic out of the nozzle is to put the nozzle/barrel assembly into the large washer upside down and prop it up on some ceramic tiles.

My hope is that by applying a heat source to the nozzle the plastic will just drip/fall out. The suggestion for using a blow torch to clear out the barrel and nozzle comes from Rick Pollack / MakerGear. Thanks again Rick!

By the way, wicked Google Sketchup skillz, no?