The spout on the black teapot on the left snapped off as I was trying to clean the model. I don’t have any ABS glue lying around so I tried white glue – which didn’t work at all. Later I held up the broken piece and the body of the teapot to my hot extruder barrel and melted them back together. Clearly not a recommended way to repair a part – but it’s been pretty effective.

Tag Archives: ABS

Am I taking this too far?

You guys are going to have to let me know if this whole “Polly/PLA” and “Abby/ABS” thing starts to get creepy. Ferris Bueller famously once said… “You can never go too far.” As far as I know, anyone who’s ever taken Ferris’s advice ended up just fine.

I’m tempted to explain the references, but I don’t want to kill the joke…

Dear Abby

I’m so sorry – I don’t know what I was thinking. I must have lost my mind. Polly meant nothing to me.

The little things just always seemed to work out between us. Sure, we had our rough patches when it came to larger things, but we learned to live with that.

You were faithful and I let you go. Abby, please take me back. 1

Yours forever more,

MakerBlock

- ABS – Acrylonitrile butadiene styrene [↩]

PLA Woes

My adventure with PLA has ended in heartbreak. It wasn’t working very well so I switched back to ABS – which was fine for a few prints. Until I found it just wasn’t extruding and stripping the filament.

So, disassemble time. My filament looked like it was getting shoved into a jam and splitting apart like a banana – with the center making it down to the nozzle through a small aperture. I found I couldn’t remove the insulator – and upon looking closer found that a very small amount of PLA had oozed down and around the nut above the insulator/ washer. I removed the extruder assembly from the ‘bot, and the heater assembly from the extruder, heated it back up and slowly removed the PTFE insulator. I found the barrel was clogged with ABS as was the insulator.

I’ve managed to clean out most of the insulator, the nut, and the threads of the barrel using drill bits and precision screwdrivers.

I’m going back to ABS, I would rather deal with warp than the heartbreak of PLA ooze into the threads of my heater assembly.

PLA versus ABS, initial thoughts

I’ve yet to print something big as I am still working out some of the black ABS specks from the extruder. Of the things I have printed so far, it looks like the PLA feels more brittle than the ABS. ABS will flex slightly when pressure is applied, whereas PLA seems to resist until it snaps. I like that I’m not wasting PLA by building rafts any more, now that the raft option is turned off in Skeinforge.

PLA takes a little longer to cool which has a few effects on a build. If the layer underneath is still molten and saggy, the layer on top will sag too. When an ABS part is done printing you’re basically ready to remove it. I find that a PLA object can still be a little soft for as much as 15-30 seconds after a build.

I’m loosing finer details on prints. I just reprinted the toy fire truck swivel. It turned out really nice except for the actual swivel part. Unlike the ABS model where the swivel snapped off immediately, the PLA model’s swivel was pretty solid (once it cooled and hardened). However, it came out too thin! As I watched it print, the PLA was so warm that it just stretched back during parts of the print – meaning the extruder nozzle made the full circuit, but the plastic stretched a little and pulled back closer to it’s last position. Uh, that may not sound like the clearest example.

Suffice it to say that small round details such as the swivel didn’t turn out very well. Which is pretty odd since similar small round detailed parts on the teapot did turn out well. I suppose part of the reason is the swivel was one small round part where the next hot layer was set down on the prior still hot layer, unlike on the teapot where the thin round spout would be drawn, then the body, then the thin round part for the handle and back over the body – so that by the time the next thin layer was set down the prior layer had cooled.

Working out

I would have thought that the PLA would have just worked out all of the black ABS out of the way already, but it’s still got the occasional black streak. Again, I don’t mind – I kinda like it. However, I would like to be able to build some pieces out of pure PLA. No matter, I’ll keep printing stripey non-cosmetic parts. :)

PLA success?!

I figured, what the hell – I built it and I can (probably) repair it, right?

So, I backed out the black ABS I have been printing in, jammed in some freaking sweet PLA, ramped up the heat on the extruder to the exact settings I use for ABS, and then FIRE THE MAKERBOT!

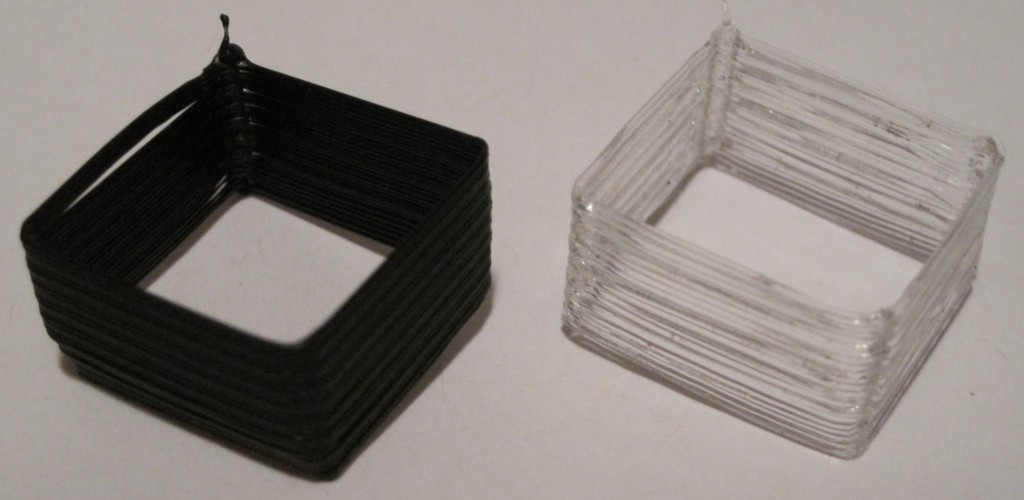

For comparison’s sake I used the same exact settings, same exact Gcode file from the last single walled test piece.

What did it look like, pray tell?

I thought you’d never ask.