Earlier I had wondered about some of the challenges facing high resolution printing. Specifically, I had suggested that a lower resolution would be better for overhangs, speed, and (after the suggestion of Erik) interlayer adhesion.

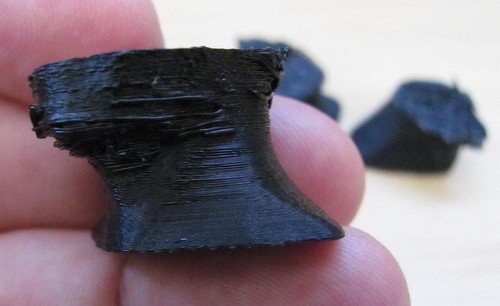

It looks like Dave Durant has a proof of concept with 1/4 of Disney’s head. 1 The layer height is unbelievably small – but as he points out:

Even smallish overhangs seem to be far harder to print at this layer height. I tried to print this one several times and it always went pear shaped as it got close to his chin, which is a pretty agressive overhang. Serious blobbage. :(

This certainly seems to demonstrate the flip side of my hypothesis – that thin layers are not good for printing overhangs. I’ve been printing with a layer height of about 0.33mm. This seems to give me enough resolution and overhang printability to make whatever I’ve needed so far. However, I think it also gives us a reason to have several different configurations for a MakerBot for each kind of plastic:

- Thin layer printing

- Good overhang printing

- High speed/thick layer printing

- Printing small holes?

What other kinds of profiles would you suggest?

- Dave – your Flickr account says all rights reserved. Obviously, I’m attributing this to you. If you would like me to remove the picture, I will do so. [↩]

I was just taking the default rights thing – I’ve changed it to “Attribution Creative Commons” which sound more lenient. Either way, feel free to use any of the stuff I’ve made public on flickr…

I’m not sure what the deal with overhangs and tiny layers is. Having spent +10 hours printing this weekend with all but one (maybe 2.. or 3.. not many, though) build coming out like crap (and most failing after 30 minutes or so instead of being polite enough to fail within a few minutes) I’ve found that tiny layers not only don’t like overhangs but they also don’t like crossing open spaces – on both, the print head catches on the lip and blobs start appearing.

I’ve had a few theories on why this happens, all of whch I decided were pretty stupid.

As I think more about this, I have a new theory as to why the tiny layers hate the open air. Maybe I’ll decide later that it’s a stupid theory but right now it seems reasonable.

I think hot ABS doesn’t like being a flat, wide layer. I think that as it starts to cool, it tends back towards being a more cylindrical shape. Not, of course, back to a perfect cylinder but in that direction instead of staying put. Maybe it’s related to surface tension. Or something.

You can see this in the pic of Walt’s head. Near the back of his neck, the layers are clearly nice & even and well behaved. On the side of his neck where it starts to overhang a little, the bits sticking out are a whole lot taller than the well behaved layers – even when the thread appears to be mostly sandwiched between the previous/next layers, the bits sticking out are thicker. Any time it tries to print over air, even if it’s just a fraction of the layer with nothing below, it loses the set layer height and ends up being taller than I want.

Once the next layer comes along and tries to extend the overhang even more, it digs into the previous overhang thickness then adds to the problem by dropping more filament over air. Pretty soon, all you have is a mess..

I guess there’s 3 things that can be done about this.. One would be a nozzle with a smaller diameter – I do have a 0.35mm makergear.com hot end that should, in theory, allow for narrower layers which means less overhang per layer. Two would be to try dropping the temperature a little – putting the plastic down at something closer to the temperature it sets at gives it less time to misbehave. Three would be to speed things up even more and try to draw the filament out and use that to decrease the width.

Maybe with all 3, it would be better at overhangs but I suspect it will just never be as good at doing them as thicker layers are…

Dave –

If you haven’t tried your 0.35mm nozzle, try it, there is a substantial difference between 0.5mm and 0.35mm nozzles…

Regarding cooling properties…a while ago I was using a glasstruder (http://www.flickr.com/photos/makergear/4176796164/in/set-72157622855375537/) for testing and saw something interesting about ABS. The glass barrel in the photo has a 4mm internal diameter and you can see that the upper section of filament is still ~3mm while the lower portion has expanded out on to the surface of the glass. When the expanded filament cooled, somewhere a little below 100C (iirc), it would nearly instantaneously transition back to the original ~3mm diameter. There was an audible snap when it happened. One second it was ~4mm in diameter and a fraction of a second later it was back to ~3mm…

Rick

Oh, I definitely haven’t forgotten about the 0.35mm nozzle!! I’m just having lots of fun playing with stuff (aka: skeinforge) I finally sorta understand. It’s nice to be able to pick a layer height & w/t that I feel like printing with and having a profile all dialed in within a few 20mm cube prints. The 0.1mm & 0.15mm profiles took a bit more creativiity but bigger sizes don’t worry much too much any more… Yay.

That’s really interesting about the ABS snapping like that with the temperature change. I know I’ve seen similar but smaller things when extruding into air, a couple inches over the platform. The snap! is not a happy sound – almost like something electric has gone quite wrong – and the filament instantly develops a kink in it. I had assumed it was something like moisture that had gotten in there but I guess it’s temperature! A little suprising given the talk of how PLA does a state change from solid to liquid but ABS doesn’t – how it’s a solidified gell or some such. We need to dig up a materials person and ask why it does this.. :)

@Dave: Thanks! I figured you wouldn’t mind. As they say, sometimes it’s better to ask forgiveness than permission… :)

As for the thin layers – I’m guessing they cool way faster than thick layers which is part of what is contributing to these problems.

@Rick: What’s the substantial difference between the 0.5mm and the 0.35mm nozzles? Besides, you know, the aperture size.

@Dave: If you understand Skeinforge, I’m going to have to invite you over to explain it to me.